Threading tools - what do you need to consider?

At BAER you will find threading tools with a wide variety of features. Material, hardening process, grinding pattern or coating - these and other aspects should be considered when choosing your threading tool. Regardless of this, we guarantee high quality and durability for all BAER products.

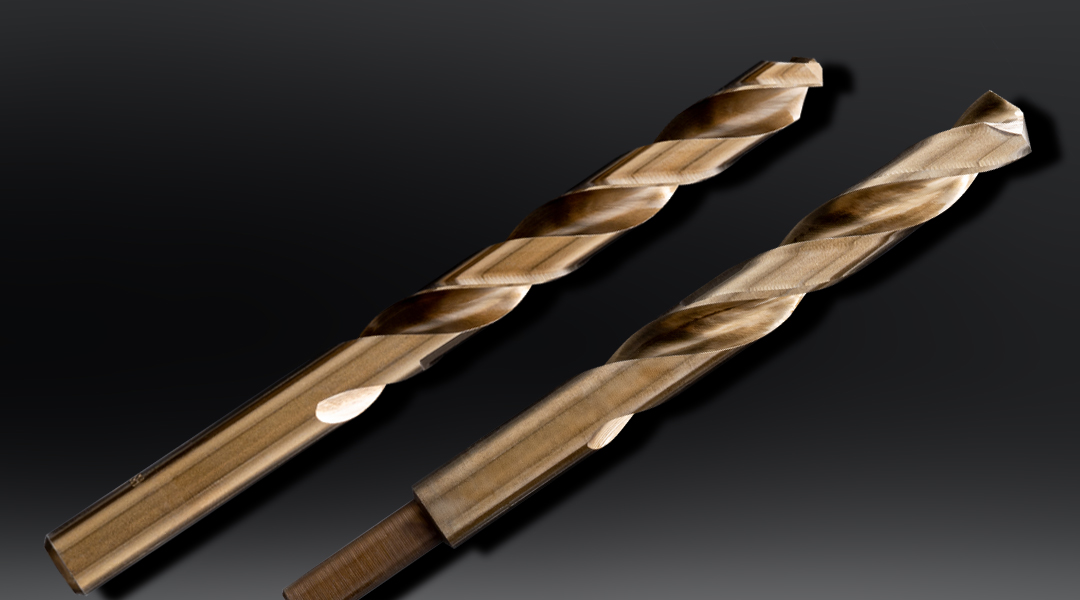

The basic material of the tap and the die

The basic material from which good threading tools are made are high speed steels (HSS). At BAER we only use high quality HSS steels from tested sources. Hand taps and hand dies are mainly made from HSS (HSSG), which has the material number 1.3343. Threading tools, such as machine taps and thread formers are mainly made of HSSE, which has the material number 1.3243. True high-performance threading tools are also made from HSSE-PM with material number 1.3294, a high-performance high-speed steel produced by powder metallurgical process, which has a very fine surface finish in the grinding pattern, as well as combining high toughness and high hardness.

Hardening process especially for threading tools

Taps and dies require a special hardening process so that you have enough hardness, but also enough toughness so that they are not susceptible to fracture. Only quality threading tools are tempered several times after the actual hardening process to avoid stresses in the material structure. Modern vacuum hardening furnaces are used for this purpose, which can regulate this accordingly with pinpoint accuracy in order to achieve the necessary results. At BAER you will find a wide range of threading tools that fulfill this quality aspect.

Micrograph of the threading tools

The main thing is the cooling and the surface of the grinding. If grinding is too hot, the material loses hardness, so that a good threading tool always requires a little more time in the grinding process. Also important are finishing adjustments, which achieve a low surface roughness. This makes the surface of the tap as smooth as possible and reduces friction to a minimum. In this way, these tools can cut smoothly in steel and stainless steel.

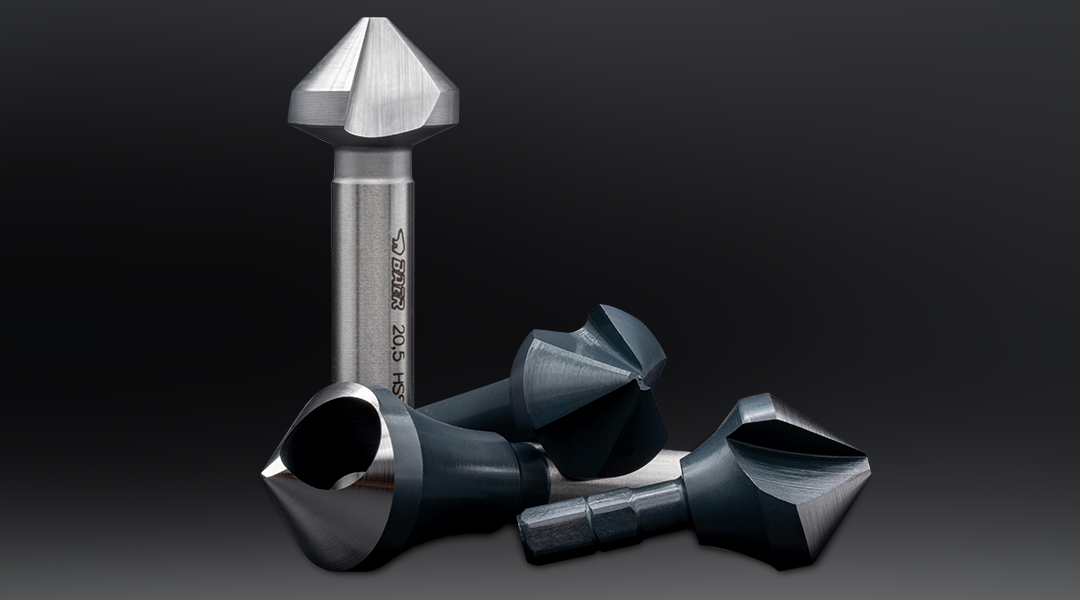

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.

Micromachining after grinding the threading tool

A really good threading tool is not finished after grinding, because it also gets a specific micro-machining afterwards to prepare the cutting edges and smooth the surface again. Since this micro-machining varies depending on the manufacturer, here also lie many secrets and special features to get out proper high-performance taps like those from BAER.

Coating and post-treatment of the threading tool

Not all BAER tools get it, but only those that are supposed to have a long service life and long durability in productions - the coating. There are some coatings that are applied in the PVD process and basically ensure that the surface becomes smoother, so the surface roughness decreases. In the second point, you increase the surface hardness enormously, so that a coated threading tool always has a longer service life than an uncoated one.

Thread technology: A book with 7 seals? BAER is the solution!

Thread technology is not quite that bad, but it is really comprehensive. There are very many different thread standards into which thread technology is divided. Among them, there are again very many expressions and thread dimensions in each of the many thread standards and additionally also the different tolerances. The thread technology deals with all variants and companies, which exist at thread connections, thus with all fastening threads and all movement threads.

We at BAER are your partner when it comes to thread technology and will be at your side with help and advice. Feel free to contact us if you have any questions. With our comprehensive expertise, we meet all challenges in the field of threading tools to offer you high-quality and durable products. Convince yourself!