This is how it works with the thread: Screw taps from BAER

From screws to screw caps - we all encounter threads every day. In trade and industry, they usually serve to hold two components together and thus literally play a supporting role for the stability and safety of machines and constructions. In order for them to do justice to this task, threads must be precisely cut. And this is exactly where the taps from BAER come into play. High-quality raw material, a great deal of care in manufacturing and 40 years of experience form the basis for our comprehensive range of thread cutters. You can rely on our quality!

A thread rarely comes alone – taps for internal and external threads

A thread always consists of two parts, an internal and an external thread. The female thread is found in the receiving drill hole or nut, the male thread on the matching screw. This means that the male and female threads always form a pair and are also standardized accordingly. When you buy taps, you should therefore pay particular attention to the correct thread standard.

Taps for external threads are called dies. On the outside of these cylindrical tools are holes for the retaining screws and a V-groove. On the inside, there are the peel cut, the threaded part with the thread lands and the chip holes. The thread lands specify the thread profile that can be cut with this tap. In addition to the round shape, there is also the hexagonal tap, which is mainly used for re-tapping and thread repair.

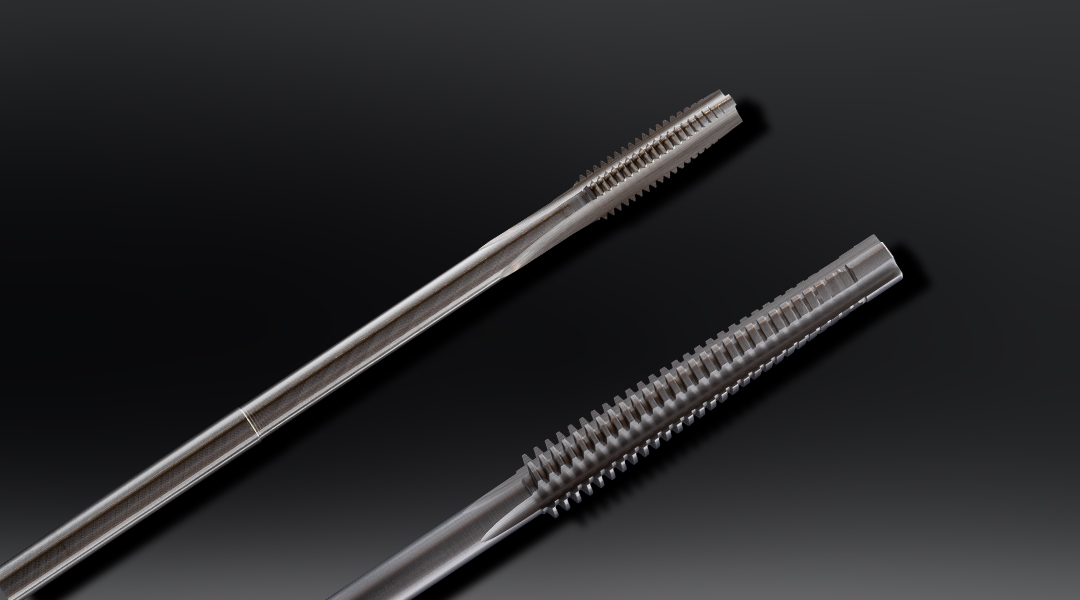

Taps are the corresponding taps for internal threads. They are drills that cut a thread in a prepared hole. They consist of a shank and a head. The thread profile on the head determines the type of thread. The dimensions for this are specified by the various thread standards. In addition, the head usually has a straight or spiral groove for chip removal. The shape of the head also indicates whether the tap is suitable for a blind hole or a through hole. A through hole is drilled completely through a component so that the tap exits on the back side. A blind hole, on the other hand, only extends a little way into the component.

Quality for long life time

The high quality of the steel we use ensures that our tools are extremely robust. Special hardening and multiple tempering processes make the hardness structure very homogeneous and offers a perfect basis for a genuine BAER tap. This increases the toughness and stability of the taps and allows them to remain in use for longer time.

Tap for use by hand or in the machine

If you want to buy a tap, then you have to choose between manual and machine use. Are you a do-it-yourselfer or craftsman and only need to cut a thread now and then in your daily work in the workshop? In that case, taps that can be used without a machine will suffice. Taps for machine use are mainly used in industry, where many threads are cut in a short time or parts are manufactured in series.

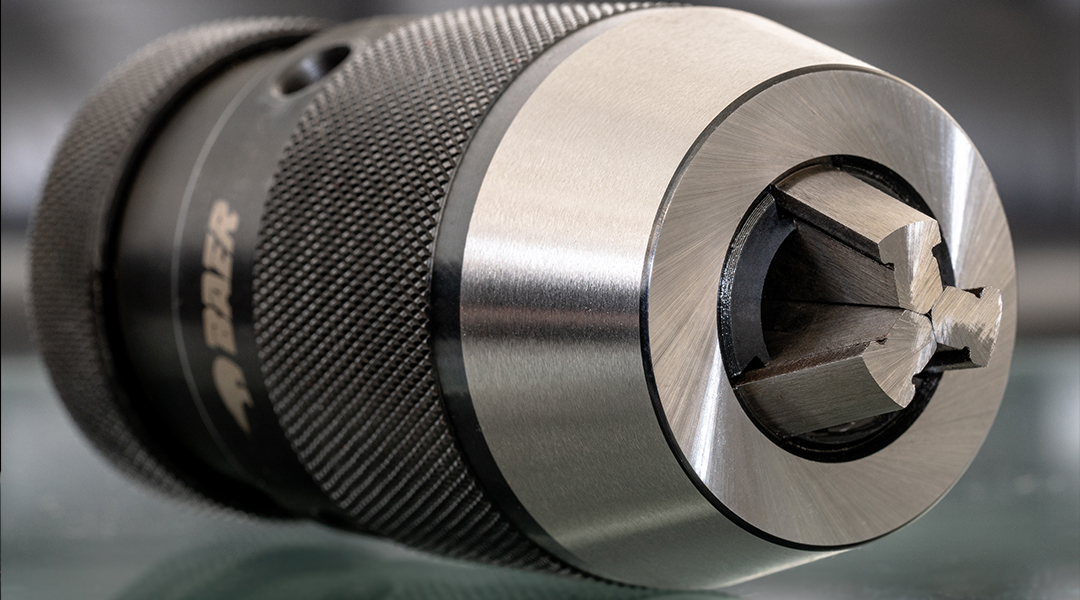

In any case, always make sure to use the right tap for your purposes. Hand taps are not suitable for machine use and vice versa. For external threads, you will need a die holder in addition to the tap when cutting by hand. For internal threads, there are special hand taps, usually offered as a tap set with three parts. Pre-cutter, middle cutter and finishing cutter build on each other in their action and are used in the specified sequence. By distributing the load over three taps, lower forces act on each individual tool, making work easier and reducing the risk of damage.

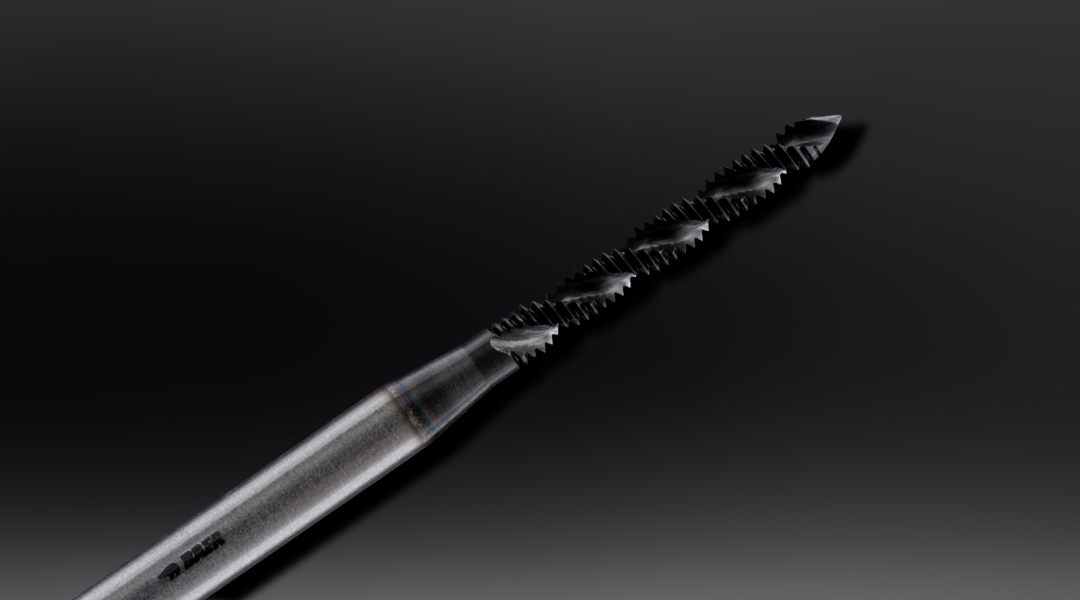

Taps for machines, on the other hand, are so-called single-cut taps. This means that only one operation is required to cut the thread. This saves time, but also requires a high level of force, which can only be achieved with suitable machines. Whether the purchase is worthwhile for you depends above all on how often the tap is used in your work.

High-speed steel: The basis for high-quality taps

At BAER we attach great importance to precision and a long service life of our taps. The basis for this is the choice of the starting material. High-speed steel, also abbreviated HSS after the English designation High Speed Steel, has optimal properties to guarantee our customers the highest quality. HSS is extremely heat-resistant and can also cope with application temperatures above 600°C, which enables high cutting speeds and very good breaking strength of our taps. In addition, it also has excellent grindability. This is noticeable in production, but also in your workshop. This is because blunt taps can be easily reground, which further increases their already long service life.

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.

Taps and more at BAER Online-Shop

In our assortment you will find all products around the topic of threads. Of course, we carry a wide range of thread cutters for every application. Not only the most widely used metric standard thread in Europe we have in the store, but also other international standards or special threads for special applications.

Especially popular are our sets and assortments. Here we have put together for you a hand-picked selection of thread cutters and other tools as well as accessories for a wide range of applications. A thread cutting set is particularly suitable if you have an increased demand or are new to thread cutting. This way, you don't have to tediously search for the tools you need, but have everything you need for your precisely cut thread with just one click. Of course, you also have the option of purchasing each tap individually, for example if you have a very specific need or want to replace a tool.

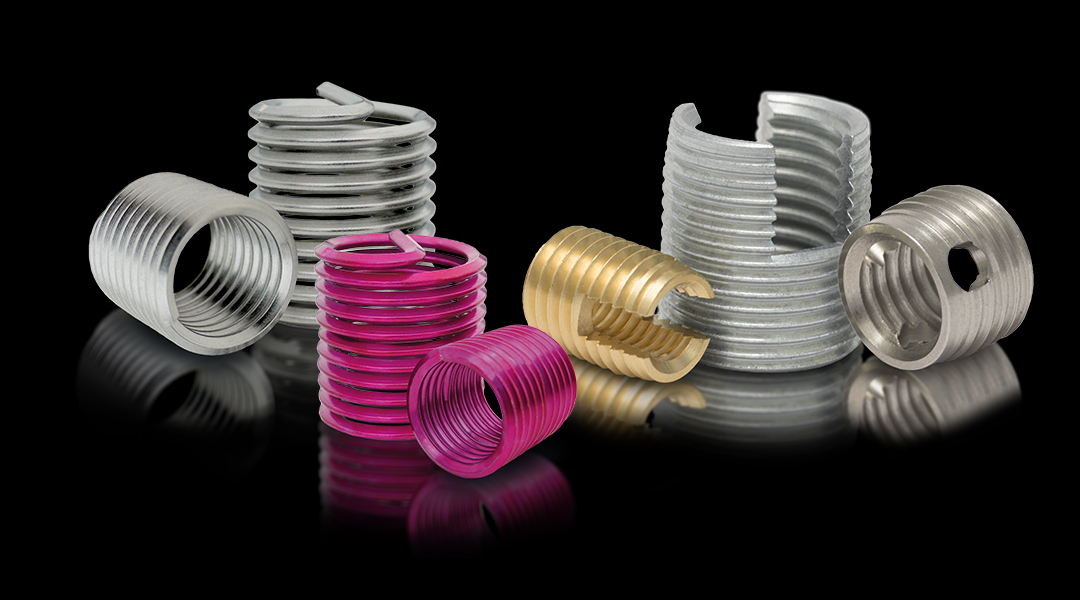

In addition to the taps themselves, you'll need a few other tools for your threading work. These include twist drills, lubricants and countersinks for optimum preparation of the receiving hole. For manual use of the tap, you will also need holding tools such as winches or die holders. We also offer inserts, assembly tools and taps for thread repair. Take a look around our Online-Shop and convince yourself of our selection!

Always there for you - The BAER customer service

For us, the customer is the center of attention. And we make no distinction between do-it-yourselfers and major customers or regular and new customers - our service is there for everyone. We want your project to succeed and you to be proud of your results. That's why we're happy to provide you with advice and support. Whether you need general information or have a specific problem, our competent customer service staff will be happy to help. Simply get in touch with us!