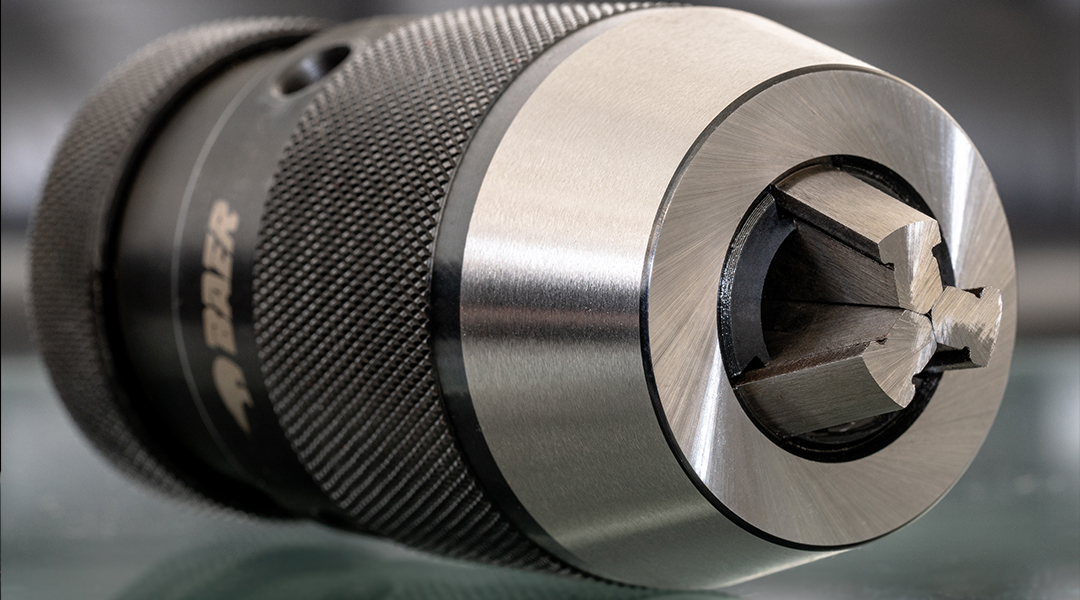

Countersink from BAER for a secure finish

The utmost care is required when working with metal, because sharp edges that pose a risk of injury and protruding burrs develop particularly quickly here. The edge of a drill hole in particular is susceptible to residues of the material, which not only look unsightly but can also quickly cause small cuts and scratches. To counter this problem, the taper countersink or borehole countersink is your tool of choice.

The countersink deburrs the drill hole and countersinks it, for example to countersink screws, so that they disappear completely into the workpiece. So not only do you remove sharp-edged residues, you also create a clean finish and a comfortable starting situation for further work, e.g. with a precision threading tool such as the tap. With a drill hole countersink, you will succeed in creating a flush surface of your workpiece without any disturbing unevenness.

As specialists in all aspects of tapping, taper countersinks are especially close to our hearts at BAER. Countersinking is not only a small but important step on the way to a perfectly cut thread. It also ensures a professional-looking end result that can't be beat for cleanliness and precision. We want you to be completely satisfied with your work. That's why you'll find the right taper countersink for your project at our Online-Shop. Take a look around and see for yourself!

This is the conical countersink: Compact design with great effect

The design of the taper countersink is as simple as it is effective. The conical head is defined by its maximum diameter and the countersinking angle. The diameter indicates the bore sizes for which the countersink is suitable. You select the countersinking angle according to your application. The range extends from 60° for pure deburring to 120° if you want to use the countersink for countersinking sheet metal rivets. The most common angle, however, is 90°, because this angle is suitable for countersinking commercially available countersunk screws. The cutting edge in the head of the countersink ensures that the material is removed, and the groove profile removes the abrasion. The shank of the countersink differs according to the machine with which you use it. The most common is a cylindrical shank, for use in hand drills there are also countersinks with a bit shank.

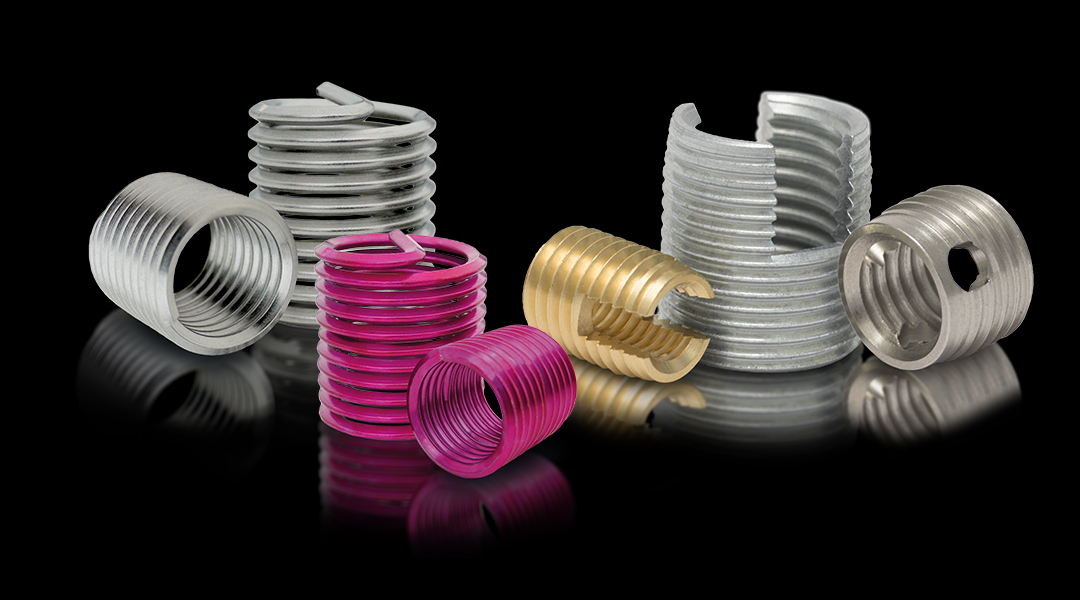

In addition to the classic form of the countersink, there are also some special variants for special cases. The transverse countersink has a larger head shape in which an opening is made. This results in a peeling cut. The chips are not discharged via a groove, but upwards through the opening in the drill head. This effectively prevents material residues from jamming in the workpiece. For countersinking cylinder head screws or hexagonal screws, you need a flat or tang countersink. Slip-on countersinks can simply be attached to an existing twist drill and are particularly suitable if you only rarely need a taper countersink.

On one view

Existing holes are reworked with the countersink:

- Deburring - for smooth cut edges

- Sinking - for countersinking screws

Find the right countersink for your requirement. Contact us.

How to use the conical countersink

If you want to use a countersink in your project to countersink screws, first measure the head of the screw. Then select a taper countersink with a suitable maximum diameter. Now you can start countersinking. When doing so, you should always work at low cutting speeds and generally apply little force. In this way, you will achieve optimum and clean results with the longest possible service life of the countersink.

How deep the conical countersink should penetrate the material depends on the desired result. If you only want to deburr the drill hole with the countersink, then a few millimeters are sufficient. When countersinking screws, however, you should use the maximum diameter of the countersink. This is the only way to ensure that the screw can really be countersunk completely and that you end up with a flat surface.

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.

Find the right countersink in BAER Online-Shop

Precision, quality and a long service life for our products - that is the BAER philosophy. And of course it all starts with the raw material used. We exclusively use high-speed steel (HSS) for our countersinks. This high quality tool steel convinces with its very good temperature properties, which allow high cutting speeds. High-speed steel can also be ground excellently. This is an advantage during production, but you as a customer also benefit from this property. This is because countersinks made of HSS can be reground should they become dulled over time. This means you can use them longer and don't have to buy new ones every time.

In our BAER Online-Shop you will find countersinks for all applications and materials. Our standard version is suitable for normal steels, cast iron, iron, sheet metal, aluminum and light metals. The use on stainless steel allows the countersinks made of HSSE with cobalt alloy and a vaporized surface. For uncomplicated use in cordless screwdrivers - whether in the workshop or in the hobby cellar at home - we have a series of bits for cordless screwdrivers in our program. And last but not least, you can choose from our cross-hole countersinks.

The taper countersinks in the BAER Online-Shop are standardized according to the specifications for metric standard threads. This makes it particularly easy for you to buy all the tools for your threads from a single source. So you can always be sure that everything fits together correctly. You can purchase the countersinks individually or look in our sets and assortments, which bring a range of dimensions.

Countersink from BAER - Quality with tradition

At BAER, we love our craft and we know you love yours. That's why we offer only the highest quality manufactured tools that give you precise work and clean, professional results. From raw material selection to delivery, we pay attention to every detail. And because we care about your satisfaction, we invite you to approach us with questions, suggestions and ideas at any time with our first-class service. You would like to know which conical countersink is the right one for your business? Do you have basic questions about the application or are you stuck with a problem? No request is too small, no project too big. Feel free to give us a try and contact our friendly customer service team!