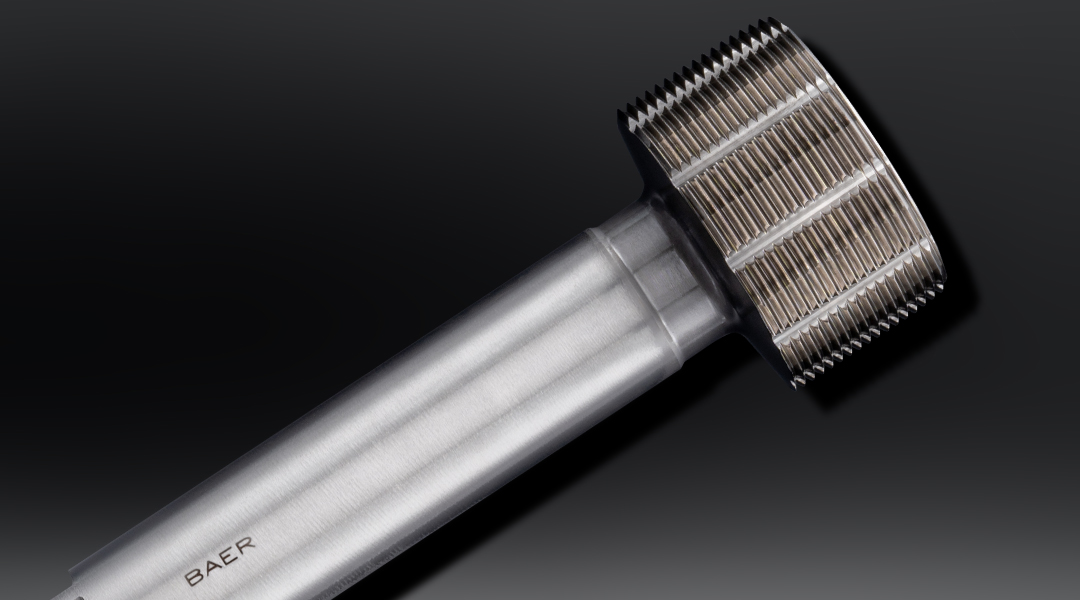

Thread former - for more strength

Both taps and thread formers are used to produce internal threads. In contrast to taps, thread formers or also thread formers have no cutting edges or grooves - at most narrow lubrication grooves. They work with forming edges and spinning dies with polygonal profiles. Since thread forming leads to compression and deformation of the grain, this results in work hardening. The result is increased material strength of the formed thread.

Especially if you do not want chips, such as in blind holes, the thread former is the first choice. According to the material to be machined, the surface of the tool can be refined.

Suitable materials for cold forming

The formin tap is used to produce internal threads by cold forming without producing chips. It requires that the material is suitable for this. For this purpose, it must have good flow properties and a minimum elongation at break of eight percent. These requirements are met by light metals, pure and precious metals, soft steels, long-chipping non-ferrous metals and soft bronze, zinc and die-cast alloys.

Unsuitable materials

Brittle, short-chipping materials with minimal elongation - such as gray cast iron - cannot be cold formed. This also applies to high-strength steels above 1200 N/mm² or AISI alloys with more than 12 percent Si content. Here, cold forming is only possible with coated carbide thread formers. The maximum thread pitch is 4 mm and the maximum outer diameter is 60 mm.

Advantages on one view

- Higher cutting speed

- Improved tool life time

- No chip accumulation: no chip jamming, no chip disposal

- Higher material strength

- Better surface finish

- No pitch errors

- No unacceptable pre-widening

- No over/undercutting

In most cases, thread production is at the end of the process chain. This makes the quality and reliability of the threading tools more important. Our experienced application engineers will be happy to advise you on the optimum technical and economic solution for thread production.

Machine taps with and without lubrication grooves

With us from BAER you will find various machine taps suitable for different materials. But why is the material important for the selection? A thread former helps you to form a thread with a higher thread strength and excellent surface structure at the same time. However, this only works if the material being tapped is cold formable!

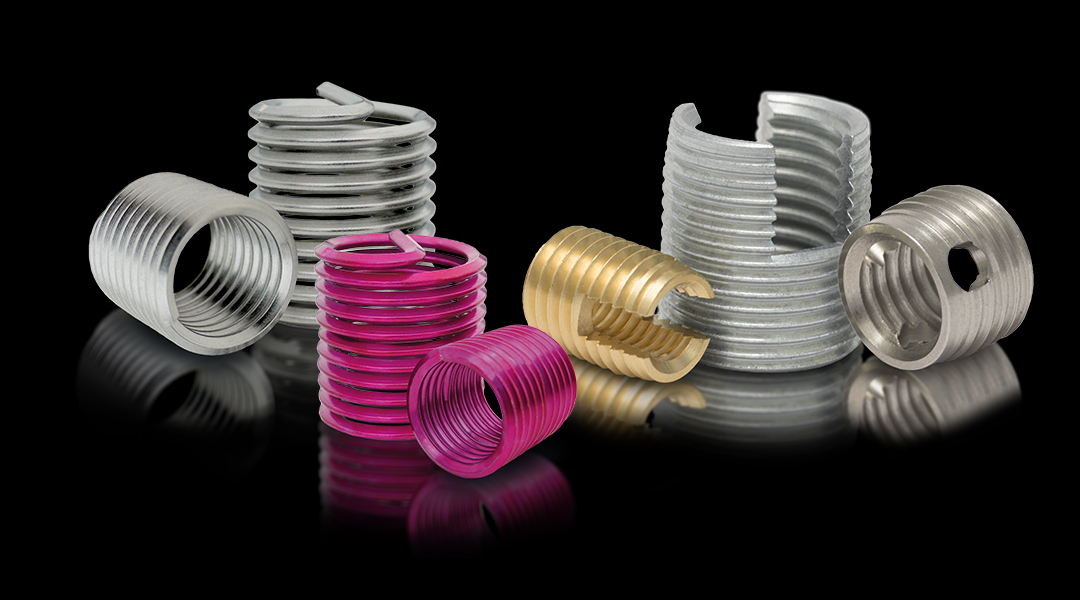

You have the choice between:

Machine taps without lubrication grooves, such as the Standard tol. 6HX - for thin and soft materials and applications up to 1.0 x diameter

Machine taps with lubric ation grooves - for through-hole threads and when working horizontally. Note: You will need more lubricant when producing larger thread depths (> 1.5 x diameter) and dimensions of 8 mm or more.

Oversize machine taps, creates threads in the upper range of the standard tolerance

HSSE-PM machine taps with TiN coating for higher hardness, better sliding properties and improved cutting pattern

Special taps - we will be happy to manufacture an individual tap that fits your requirements and that you cannot find in our range. Please do not hesitate to contact us!

Advantages of TiN coating

If you choose a tap with TiN or titanium nitride coating, you will have several advantages at once:

- Not only is this type of coating ideal for taps and taps, but it is also suitable for other tools you use for drilling, machining or forming, or even plastic forming.

- In addition to versatility, this coating guarantees wear protection and improves the demolding of injection molds.

- The coating is visually appealing, as the golden color is very attractive - it therefore serves to easily identify a high-quality tap.

Suitable materials for the tap

When using the thread former, you must make sure to use only materials suitable for cold forming.

The thread former is used to produce internal threads by cold forming without producing chips. The prerequisite is that the material is suitable for this purpose. To this end, it must have good flow properties and a minimum elongation at break of eight percent. These requirements are met, among others, by light metals, pure and precious metals, mild steels, structural steels, stainless steels, free-cutting steels, long-chipping non-ferrous metals and soft bronze, zinc and die-cast alloys.

Unsuitable materials for machine taps

Brittle, short-chipping materials with minimal elongation - such as gray cast iron - cannot be cold formed. This also applies to high-strength steels above 1200 N/mm² or AISI alloys with more than 12 percent Si content. Here, cold forming is only possible with coated carbide thread formers. The maximum thread pitch is 4 mm and the maximum outside diameter is 60 mm.

Advantages of thread forming

- Higher cutting speed or forming speed

- Improved tool life

- No chip accumulation: no chip jamming, no chip disposal

- Higher material strength

- Better surface finish

- No pitch errors

- No unacceptable pre-widening

- No blending

Restrictions to be observed in thread forming:

- There are higher requirements for borehole tolerances in thread forming

- There is a higher heat generation than with thread cutting

- The tap is not suitable as a hand tool

- You cannot use the tap for external threads

- The thread former can also not be reground

- The achieved thread quality always depends on the quality of the lubricant

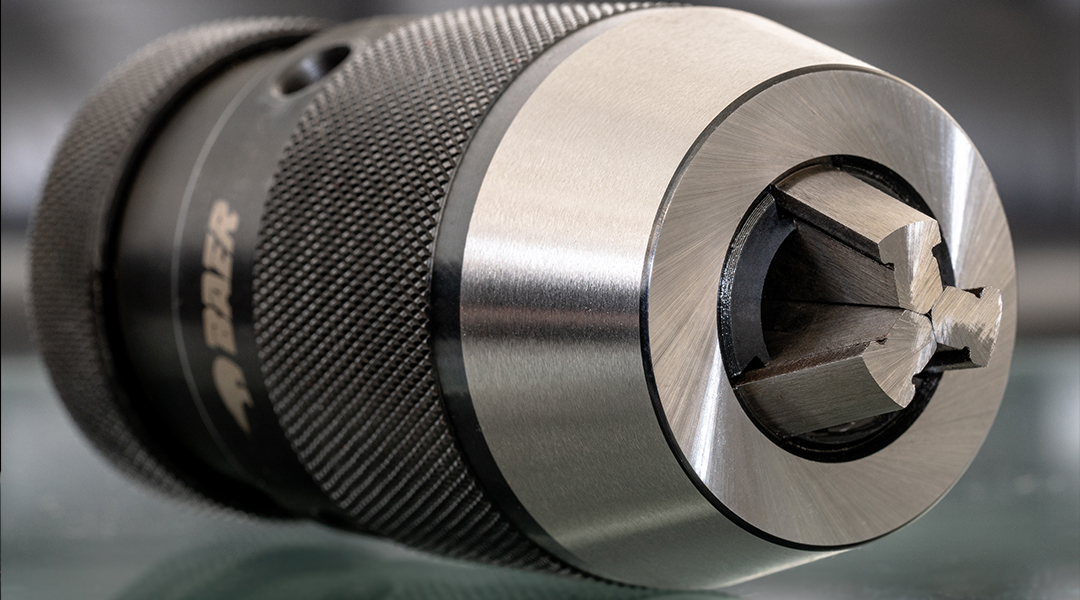

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.

Common mistakes that you can avoid when forming threads, however

The thread only enters the workpiece at the end - if something goes wrong now, it could possibly cost a lot of money. With our high-quality thread formers, you are basically well equipped, but mistakes could still happen that have nothing to do with the thread former itself.

Therefore, pay attention to the following common sources of error:

- An unclean thread surface occurs. There are several possible causes here, which you can eliminate from the outset. Make sure you have good cooling lubrication and a sufficiently high oil concentration in your emulsion, as well as good material adhesion to the tool.

- It can happen that the thread is not fully formed. The trigger for this is usually a pilot hole that has been selected that is too large.

- The thread could be overformed. In this case, the diameter of the pilot hole was selected too small and possibly an insufficient cooling lubrication with too low an oil concentration.

Why does lubrication play such an important role in the thread former?

Without sufficiently good lubrication, the lubricant film can tear and material welds can occur as a result. These lead to unclean thread surfaces or even - which is even worse for you - to tool breakage. The lubrication grooves on the tap optimally support the lubrication effect even with deep threads. This improves the tool life and the thread surface at the same time.

Difference between tap and tap former

You can make a thread not only with the thread former (also called tap), but also with a tap. But what is the difference?

- The thread former is more resilient than the tap and therefore has the longer service life.

- The thread and the surface are better with the tap because here no material fibers are destroyed during the process.

- The tap can produce internal threads without cutting and this quickly and precisely.

- The tap is more suitable for larger thread depths than the tap.

Buy thread formers - now with the professionals from BAER

In most cases, thread production is at the end of the process chain. This makes the quality and reliability of the threading tools all the more important. Our experienced application engineers will be happy to advise you on the optimum technical and economic solution for thread production.

That is why our Online-Shop is the best choice for you if you want to buy a thread former:

It makes us happy when our customers are satisfied. That's why we place the highest value on courteous customer service, from detailed purchasing advice to expert customer support. You can trust our many years of expertise and ask our service staff anything that is on your mind.

Our quality must always fit, too. Therefore, we ourselves set the highest standards for our high-quality products. We buy only the best raw materials and choose the right supplier, but above all, we attach great importance to a precise manufacturing process, which is rounded off by meticulous final inspection of the goods. This way we can ensure that only excellent products leave our premises. We are also always striving for new developments to make it easier for you to work with our tools and to deliver excellent results quickly.

Convince yourself of our products and our service now and order the thread former of your choice at Baer Online-Shop! Do you have any questions about taps? Then please contact us in writing or by phone!