BAER Thread gauges - Checking threads with dimensional accuracy

With BAER thread gauges you can accurately check your internal and external threads. Measure whether your metric thread complies with the standard in no time with the help of the thread gauge. Our thread gauges in the form of plug gauges or ring gauges ensure exact dimensional accuracy during measurement. On request, we will be happy to have the thread gauges manufactured for you according to DIN, ISO or ANSI and send them with an enclosed test certificate. This way you can be sure that everything is correct with your threads.

The quality of your thread is crucial for the overall operation of your component. That's why we also guarantee you optimum quality for testing your threads. Made of high-quality special gauge steel, the thread gauges from BAER are particularly durable. This means that internal and external threads can be reliably tested for a long time.

The right thread gauge for internal and external threads

With the BAER thread gauges, your thread finally complies with the common standards, because you can check it reliably and regularly. For this purpose, however, you should also maintain the common room temperature (approx. 20°C). Because otherwise it can come to an expansion of the components, which falsifies the result. The overview of our wide range shows which are the right thread gauges for your internal or external thread.

Thread gauges for testing internal threads

The standard for a thread limit plug gauge of the metric internal thread is DIN ISO 1502, according to which the thread gauge must be manufactured to accurately test an internal thread. In our offer you will find gauges that can be used to test a wide variety of threads. You will find the right gauge for standard, coarse and fine threads as well as for pipe or trapezoidal threads.

Thread plug gauge: With this thread gauge you can test your metric internal thread quickly and reliably. This is because this thread gauge is equipped with a standardized thread profile, which should be able to be screwed in optimally and precisely when threading. The fine grinding as well as the precise finish ensure a very accurate measurement that you can rely on. If the thread corresponds to the tolerance, the thread-good plug gauge can be screwed into the thread completely and without force.

Thread Reject Gauge: Test in a flash whether your internal thread complies with the standard. This thread gauge makes it easy and reliable. Simply screw it into your thread and test whether the pitch diameter exceeds the standardized dimension or not. This is the case if it can be screwed into the thread more than two turns.

Thread limit plug gauges: This is our two-in-one solution in thread testing. That's because this plug gauge conveniently combines a thread-gauge plug gauge and thread-exclusion plug gauge. To test your thread, simply screw the good plug gauge side into the appropriate thread. If the thread is well standardized, you should be able to screw it in completely without any problems. You can also check this more closely with the scrap side. Because if this shortened side can be screwed into your thread more than two turns, you can be sure that it does not comply with the standard and the pitch diameter is too large.

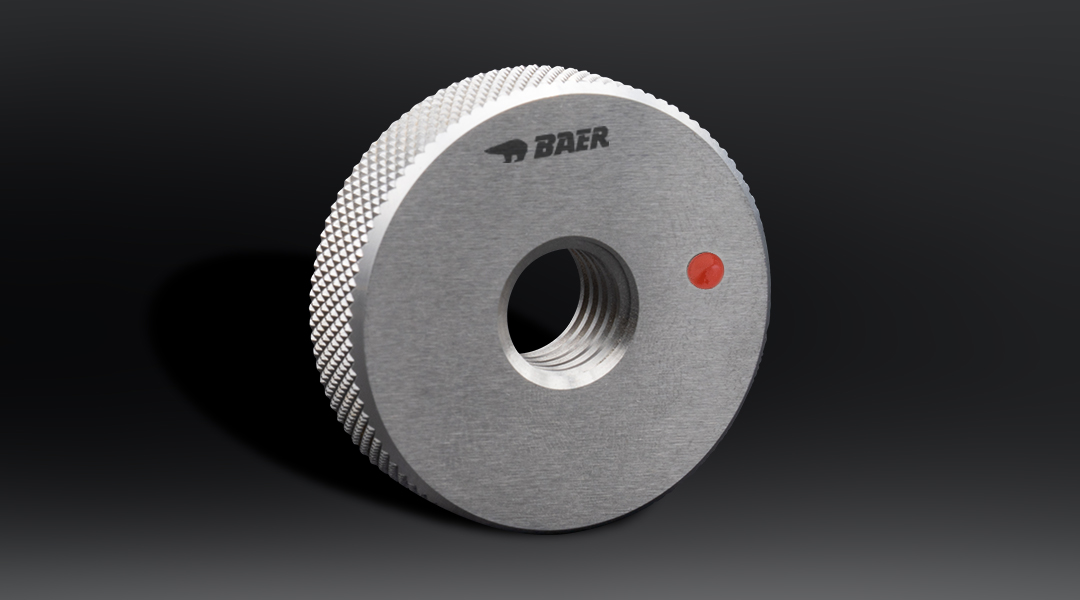

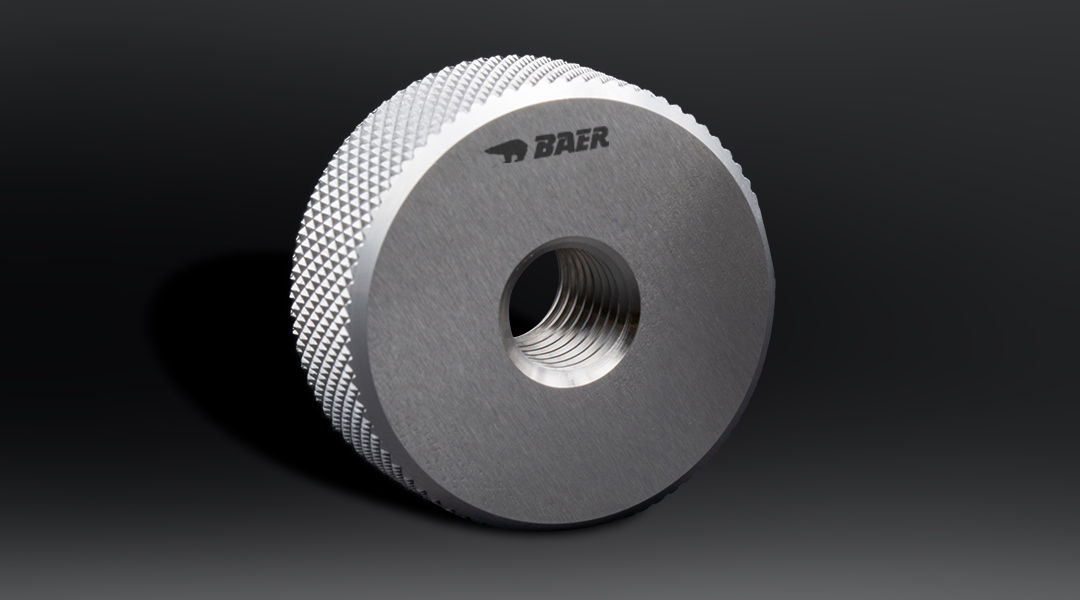

Checking external threads – the right thread gauges

Also to test your external thread, BAER provides you with the right tool. For testing external threads, thread ring gauges are an optimal choice. Again, you will find a selection for different requirements.

Thread Gauge Rings: This thread gauge should be able to untwist completely on a thread that complies with the standard. However, the wear of this tool should also be checked regularly for best results.

Threading Scrap Ring Gauge: Unlike the Good Ring Gauge, this threading gauge is shortened. This means: In this case, the ring should not be able to be unscrewed by more than two turns. If it exceeds this dimension, the thread is too small and does not correspond to the dimension and standard it should have.

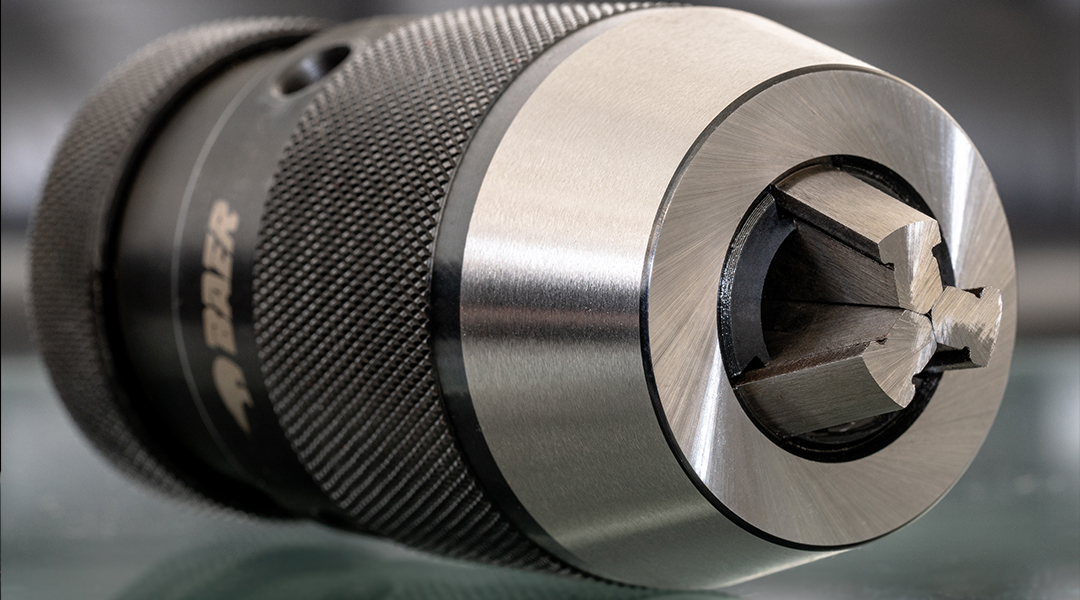

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.

Buy thread gauges and accessories at BAER

BAER has been your reliable partner in thread machining for 40 years. Buy thread gauges in our online store and benefit from outstanding quality, the best price-performance ratio and competent advice from our experts.

With our many years of experience, we equip professionals in the thread machining with professional tools that are as strong as an ox. In addition to thread gauges, you will also find everything else in our online store that you need for accurate and optimal threads.

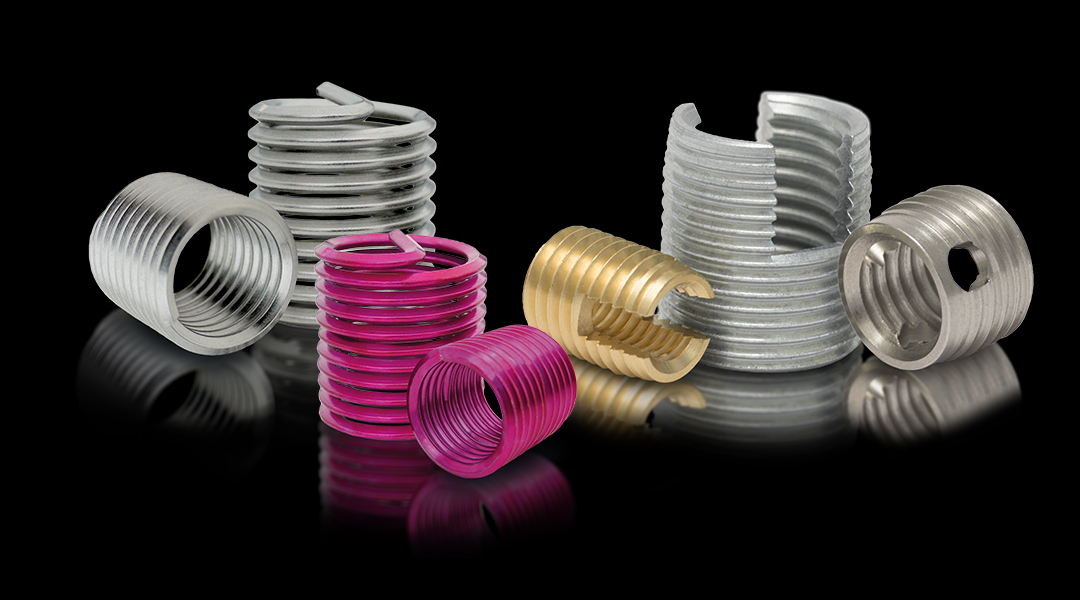

To repair or strengthen threads, be sure to check out our powerful thread inserts from BaerCoil and BaerFix. You'll also find entire repair kits to quickly and reliably fix broken or worn threads.

If the thread you measured with the thread gauge does not meet the standard, you can recut it with a thread restorer or bring it into the right shape with a thread former.

Of course, you will also find a large selection of taps and thread cutters for thread production. If you have any questions, please feel free to contact us and we will help you with competent and professional advice. Discover a versatile online store that offers you everything you need for thread machining.

Buy thread gauges easily and conveniently online

We at BAER make it easy for you. When you choose a thread gauge from the online store of BAER Tools, you not only benefit from outstanding BAER quality, but also from many purchasing advantages. Simply choose from our many payment options which suits you best. Whether PayPal, invoice or credit card is entirely up to you. Not only do we attach great importance to the safety of our tools, but our shipping is also fast and reliable.