Why BAER is the right partner for thread taps

BAER Tools GmbH is your specialist manufacturer of high-quality tap drills, thread formers, and thread cutting tools – for industry, trade, and demanding DIY enthusiasts. For over 40 years, mechanical engineering, automotive, trade, and DIY users have relied on our precise and durable tools.

As an ISO 9001-certified company, we combine precision manufacturing, practical expertise, and high-quality materials. This results in tap drills and threading tools that guarantee clean cuts, long service life, and consistent thread quality – even for customized special solutions.

Your advantages with BAER thread taps:

- Large selection of machine and hand thread taps for professionals and DIY enthusiasts

- Over 10,000 items available immediately from stock

- Quality manufacturing – ISO 9001 certified

- Technical advice and customized special solutions

- Fast delivery and direct access to the BAER Online-Shop

Now in the video: BAER threading tools work so well in practice!

Taps for industry, trade, and demanding users

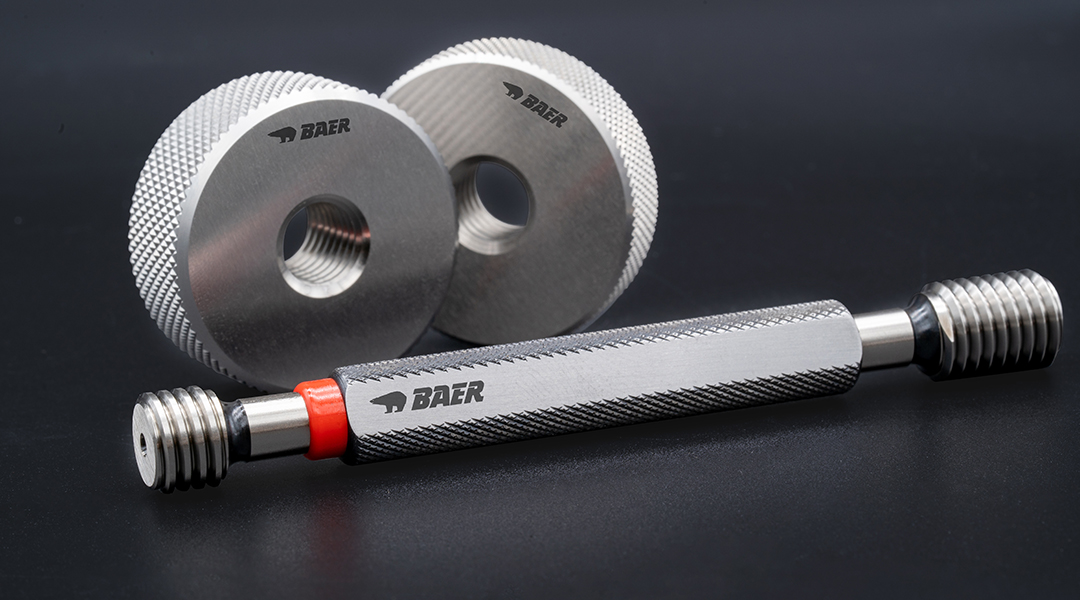

With BAER threading tools, you can cut, shape, test, and repair threads precisely, cleanly, and durably.

Our thread taps, thread formers, dies, and thread gauges impress with their exact fit, easy handling, and long service life – ideal for industry, trade, and demanding DIY enthusiasts.

BAER threading tools stand for decades of experience, innovative manufacturing technology, and precision Made in Germany—for reliable performance, perfect threads, and consistent quality in every application.

For example, choose between the following thread taps:

Questions about product selection?

Not sure which tap is the right one? Our team will be happy to help you!

Order online now from thread cutter manufacturer BAER – Quality from Germany

BAER is a second-generation family business and manufacturer of high-quality taps and threading tools. We accompany every tool from raw material to delivery – at BAER, everything comes from a single source. This ensures that our products always offer the precision and quality that industry, trade, and demanding users expect. With our own production facilities in Germany, many years of experience, and consistent quality control, we stand for reliability and customized solutions – even for special designs.

Discover the entire range of our BAER thread taps and threading tools in the BAER online shop. BAER delivers reliably – throughout Europe and with short delivery times thanks to modern warehouse logistics.

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.

BAER – Quality that lasts. Service that delivers.

f you want to drill perfect threads, you need tools you can rely on. Our thread taps stand for maximum precision, long service life, and clean cuts—even with demanding materials. Whether for industrial series production or use in the workshop: with BAER, you can be sure of professional results and save time, rework, and costs.

Our service? Fast, solution-oriented, and personal if required—from the first click to punctual delivery.

Discover the right tap drills now and order them directly online.