Step drill for drilling in metal and plastics

Whether you're a do-it-yourselfer or a craftsman, you're bound to come across areas of application where you can't get far with your standard equipment. Precision threading tools then enable you to continue working precisely and efficiently instead of settling for makeshift alternatives. When drilling holes with large diameters, for example, conventional twist drills quickly reach their limits. And that's where the step drill for metal and other materials comes in. Thanks to its special design, an HSS step drill not only enables an enormous diameter of up to 45 mm, it can also complete several work steps in one.

Classic applications of the drill are the drilling and reaming of sheet metal, pipes and profiles. It is therefore hard to imagine the automotive and aircraft industries, mechanical engineering, control cabinet construction and the electrical industry without step drills. And even though step drills are designed for metal and plastic, they can also be a good choice for wood and other materials.

Are you thinking about buying an HSS drill? In our BAER Tools Online-Shop you will find a comprehensive selection of high-quality step drills made of high-speed steel. Whether you're in a hobbyist's basement or in industry, our step drills are suitable for any application and can handle heavy loads. At BAER, we want you to be able to complete your project with pride and without frustration. Customer satisfaction is our number one priority, so we work hard to bring only the best quality to the market. You can count on that.

What makes the step drill so special?

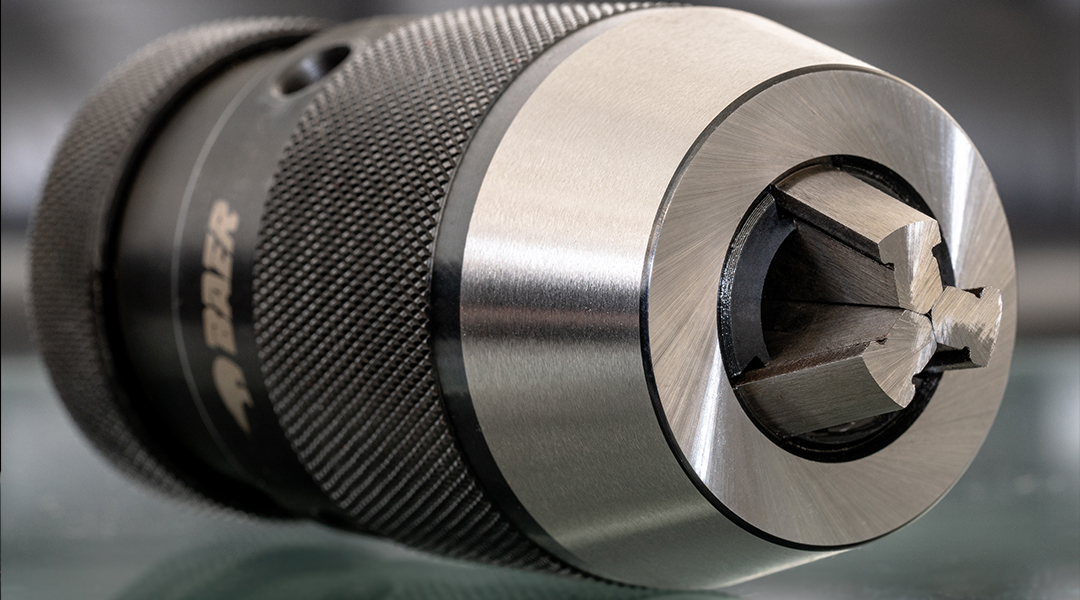

The drill stands out as a special drill at first glance. Unlike a conventional twist drill, the shape of the step drill is not cylindrical, but conical. Specifically, this means that it starts with a point and the diameter gradually increases downward in several steps. However, due to the step shape, the walls of the holes thus created remain straight. This also distinguishes it from the peeling drill.

In its shape, the step drill is somewhat reminiscent of a Christmas tree. The tip is similar to that of a twist drill. It also tapers at a small point angle and is ground. This makes it easier for you to center and spot drill when working with the step drill on metal and plastic. The main part of the drill consists of the eponymous steps, the number and diameter of which determine the size of the step drill. In addition, the step angle is also an important value. This determines how easy the transition from step to step is during drilling. The height of the individual steps, in turn, determines the maximum thickness of the material in which the step drill can drill a hole with straight walls. They also have spiral grooves for chip removal.

And this is how working with the step drill works

The application of the drill is not complicated. The step drill even relieves you of work steps that you would have to do separately with other drilling methods. Nevertheless, there are some points that you should consider when you decide to use a step drill for the first time.

Such a drill combines in a single product the possibility of creating up to 15 different diameters. So, unlike a twist drill, you can not simply use the step drill to the limit, but must stop in time. To do this, you first determine the desired diameter of the hole you want to drill. Then you match this with your step drill and determine which step this selected diameter corresponds to. When using it, you must now take care not to drill beyond this step. The easiest way to do this is to make a corresponding mark with a wipeable pen.

Thanks to the small point angle and the pointing, the drill can now be centered easily and you can start drilling directly. To deburr the drill hole, you then use the next step of the step drill in each case. All steps with one tool - this saves time and enables particularly fluid work.

Due to its special shape, high friction can quickly occur when drilling with the step drill. You should therefore always use a cutting oil to keep this effect to a minimum. In addition, depending on the model, they are only suitable for materials with a thickness of around 4 to 6 mm.

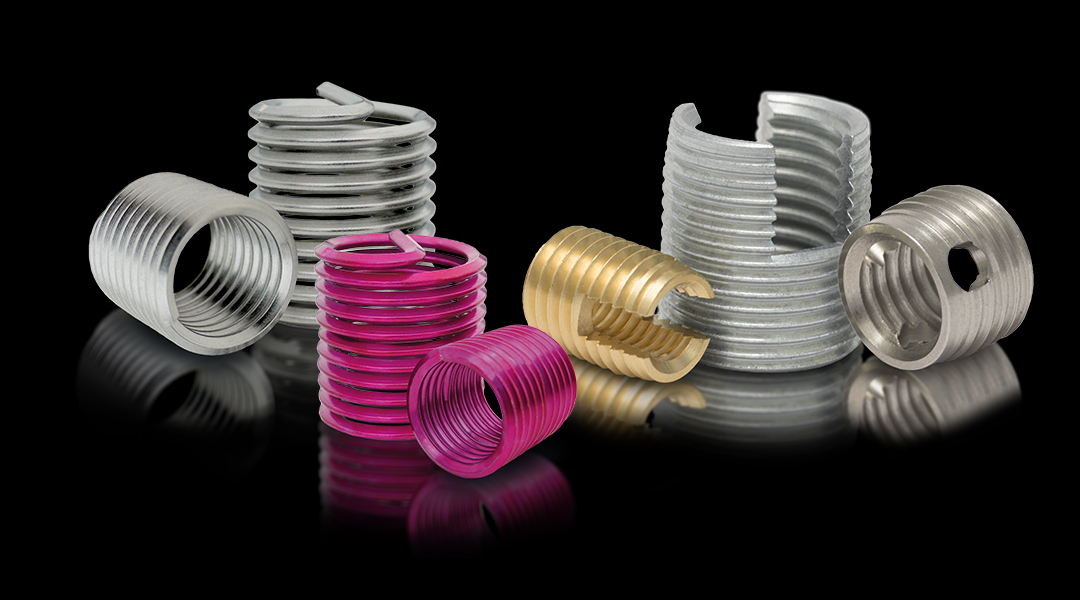

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.

Buy step drills at BAER - for quality you can rely on

At BAER it is important to us that you can work efficiently with our tools for a long time. Therefore, we attach great importance to high-quality starting materials. We only use high-speed steel (HSS) to manufacture our drills. This is a high-alloy tool steel that does not break down even at application temperatures of over 600 °C and thus permits particularly high cutting speeds. It is also very fracture-resistant and easy to grind. And this is not only an advantage in manufacturing. HSS step drills can also be reground when they start to become dull after long use. This is not only easy on your budget, but also makes a valuable contribution to greater sustainability.

In our BAER Online-Shop you will find both HSS drills for cable glands according to DIN EN 60423 and step drills for metal such as structural steels, CrNi steels, non-ferrous metals and stainless steels. With us you can buy step drills that serve all common size ranges. From 4 to 45 mm in 8 to 15 steps, we offer you the right tool for every application. In addition, we have sets and assortments ready for you, so that you can also buy a set of step drills that covers all diameters from 4 mm to 30 mm with different drills. This guarantees that you always have the tool you need at hand.

You are unsure which is the right drill for your project? You would like to clarify open questions before you decide to buy a step drill? Then please do not hesitate to contact us. We will be happy to advise you on our HSS step drills and answer all questions on the subject of step drills with expertise and the experience of 40 years of company history.