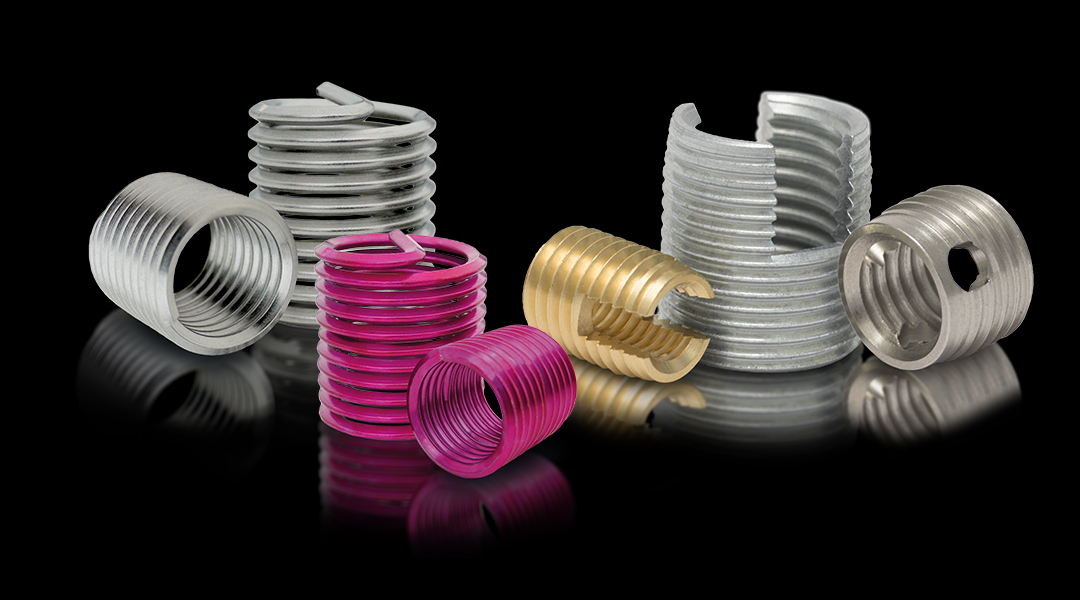

Fasteners such as bolts or nuts can be damaged during use or if used incorrectly. However, by external thread cutting or internal thread cutting with a thread restorer, the thread can be repaired and accurately restored.

The great advantage of using our BAER Thread restorers is that the thread itself is not changed in its dimensions during external thread cutting. In addition, it is fully functional again after the repair, i.e. tensile strength, heat and vibration resistant. As a result, the thread is subsequently ready for use again, even in critical applications. Save your fastening products with internal threads or bolts with external threads now with our high-quality thread restorers.

Thread restorer - as good as new again

The universal BAER thread restorers can be used to recut internal and external threads. You can flexibly set the desired diameter. This enables the use of one tool in different thread standards and dimensions. Damaged or dirty threads can be quickly and easily repaired and freed from rust. Important: Even after repair, the thread is tensile and resistant to heat and vibration.

We currently carry the following popular products:

For external thread cutting: Our thread restorer for external thread is suitable for a wide range of thread types such as: M, MF, UNC, UNF, UN, NPT, G-TUBE, BSW, BSF, BSB. It allows you to very precisely cut an external thread and then reinsert it in a fully functional way.

For internal thread cutting: Our thread restorer for internal threads is designed for clean and accurate recutting of internal threads. You can use it to reconstruct right-hand and left-hand threads without altering the thread in the process.

Advantages:

- The application is very simple

- The original thread is reconstructed but not changed

- Rust is removed at the same time

This is what BAER thread restorers do

It is worthwhile to restore threads by the internal thread or external thread cutting. In this way, you extend the service life and save effort and costs. You reconstruct the old thread without changing it. This means: the dimensions remain the same and you can continue to use the same screw size. In addition, they are suitable for right-hand and left-hand threads.

Would you like to know more about how to repair your thread? Simply contact us and we will be happy to give you practical tips.

Internal thread cutting and external thread cutting

In industrial metalworking, for example in the production of fasteners and fixing elements, internal and external thread cutting is part of the daily production steps. But also craftsmen, car hobbyists or do-it-yourselfers benefit from devices for external thread cutting in order to restore and reuse existing fasteners. It's also more sustainable and cost-effective.

Possible applications:

- Internal thread cutting is possible on a nut thread

- External thread cutting can be performed on bolt threads or screws as well as on threaded rods.

Internal and external thread cutting can be performed in various materials such as wood, metal or plastic . It also doesn't matter if you want to perform external thread cutting on a fastener, movement or transport thread.

The differences between these types of threads are the different load requirements. The fastening thread, for example, is intended to serve as a secure and strong connection between a nut and bolt. A movement thread is intended to allow rotational movement (such as in presses or vises), and a transport thread is found primarily in agricultural machinery or water conveyance (augers).

Production and finishing of threads

Internal and external thread cutting differs in post-processing from the manufacturing process.

- External threads are produced either by forming or thread cutting, i.e. non-cutting or cutting. Chipless manufacturing is preferred in the industry because it is more efficient and yields better strength and smoother surfaces. External thread cutting is performed during manufacture using a die.

- The internal thread can be created using screw taps or taps, both by machine and manually. Taps, self-tapping screws, thread-forming screws or milling machines are also used.

TIP: At BAER you will of course not only find the right tools for restoring threads, but also for thread production. We offer high quality and durable taps, thread formers, dies and all other necessary tools in our store!

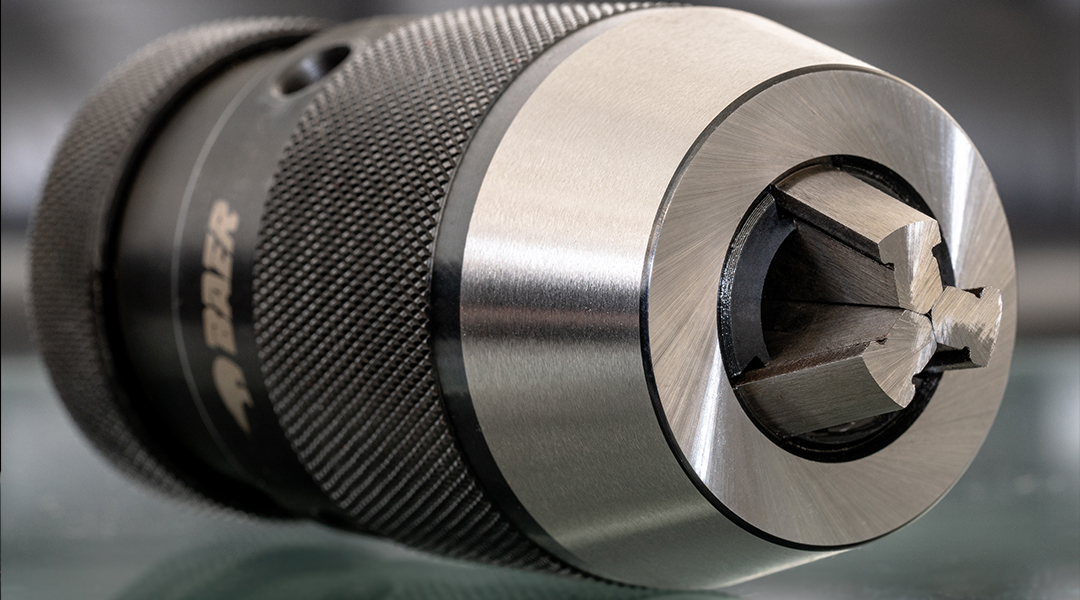

Instructions on how to use the thread rest orer and info on internal and external thread cutting can be found in the respective product description in the store. The restorer is easy to apply and turn and recuts the thread very precisely. For external thread cutting, all you have to do is open the handle of the blades and insert the screw for a precise fit. Then close the handle, tighten the thread by hand and turn the restorer.

Do you have any questions or problems with the application? We are always available to answer your questions and provide support in writing or by telephone. This will make internal and external thread cutting a breeze for you!

Thread restorer for internal and external thread cutting in best quality

BAER is known for its modern and innovative tools in various fields of application. Here you will find an extensive range of highest quality tools for professional use in industry and trade, but also for ambitious do-it-yourselfers.

We always have the right thing for you - and if not, you can benefit from our individual custom-made products. Just tell us what you need and we will make it for you! Feel free to contact us and receive our informative offer as soon as possible! We are already looking forward to hearing about your special requirements.

For us, not only excellent products are part of customer satisfaction, but also excellent advice and fast delivery. Feel free to discuss the purposes for which you are looking for the right tool with our friendly customer service staff even before you place your order. We will then help you with the selection and of course explain the correct application! Even after your purchase, you are not on your own, because even then we are happy to help you if you have questions or problems.

Use our comfortable and clearly arranged store for your online orders now and take advantage of our competent advice. You can always contact us in writing or by phone!

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.