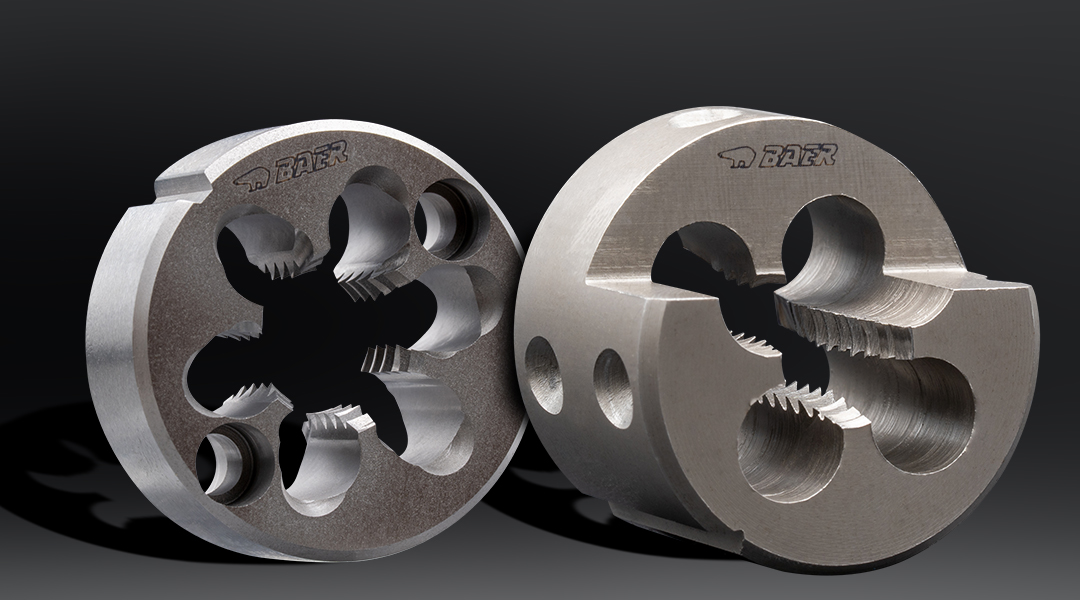

Thread cutting dies from BAER for precise external threads

Are you looking for a precise tool for a perfect external thread? Then BAER dies are the optimal choice. They cut screws and bolts effectively and accurately. Whether brass or steel, our dies take on any material. Simply choose the right die for your material from cylindrical, hexagonal or round variants.

Our dies can be operated both manually and mechanically. What's more, you can always count on compliance with the highest quality standards. With many years of experience in thread processing, BAER has been your partner for the best and highest quality tools for 40 years. Outstanding quality and a fair price-performance ratio are a matter of course for us.

Practical threading dies in unbeatable BAER quality

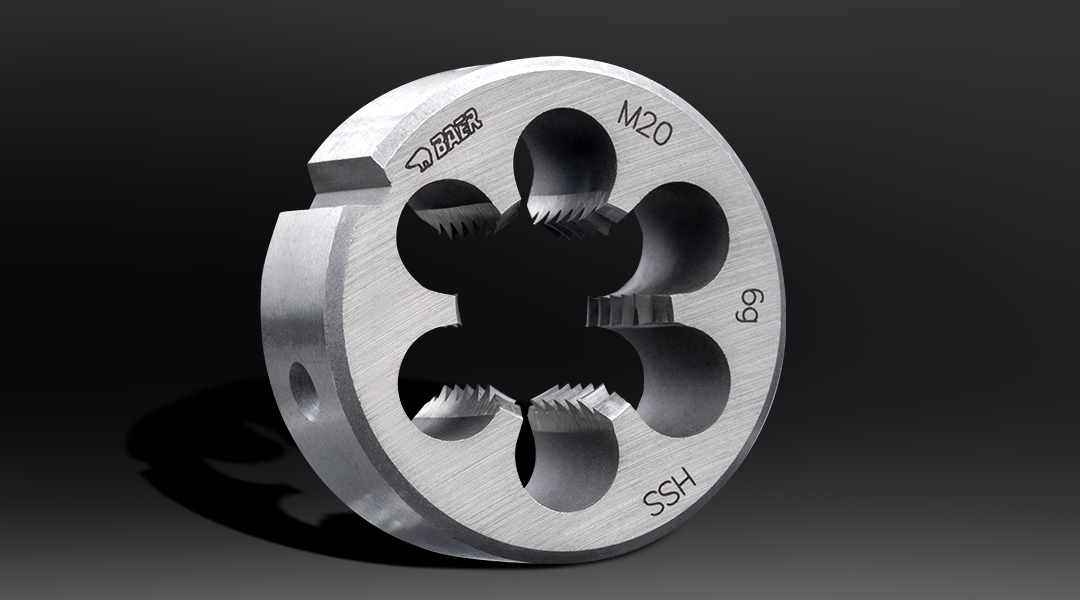

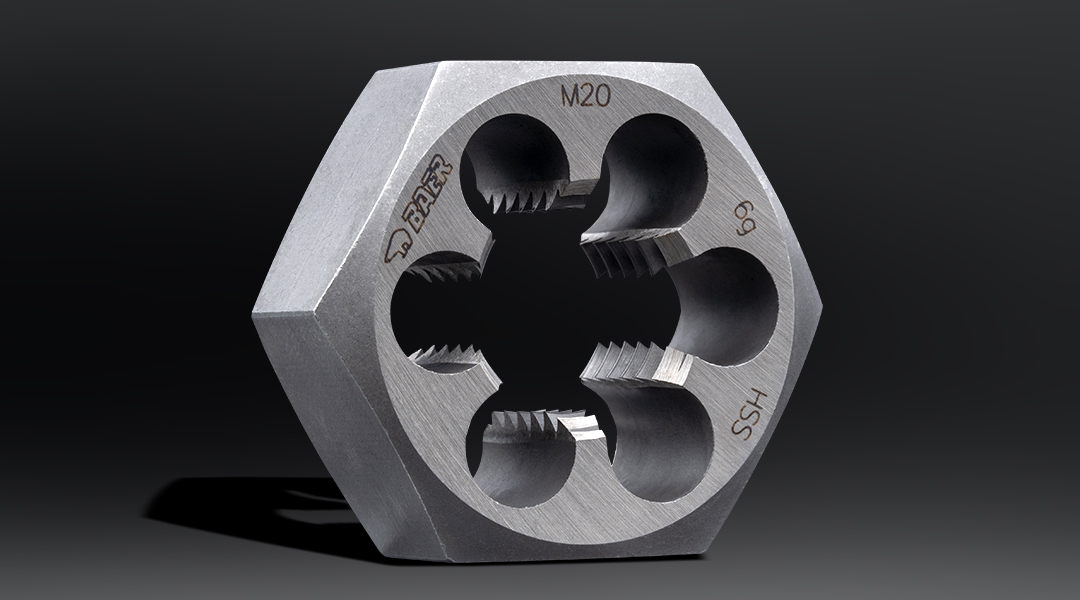

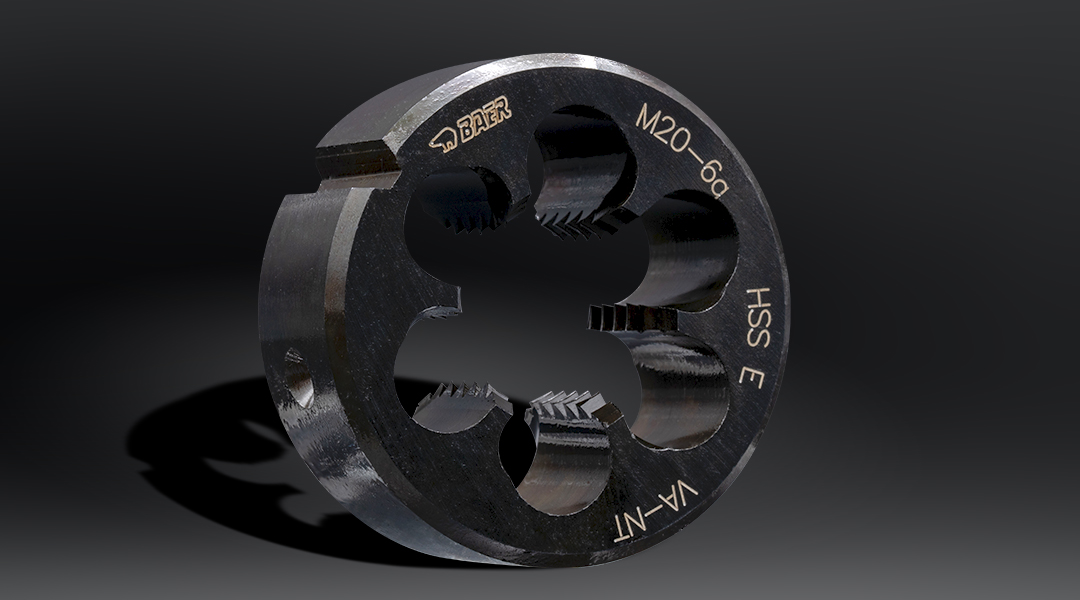

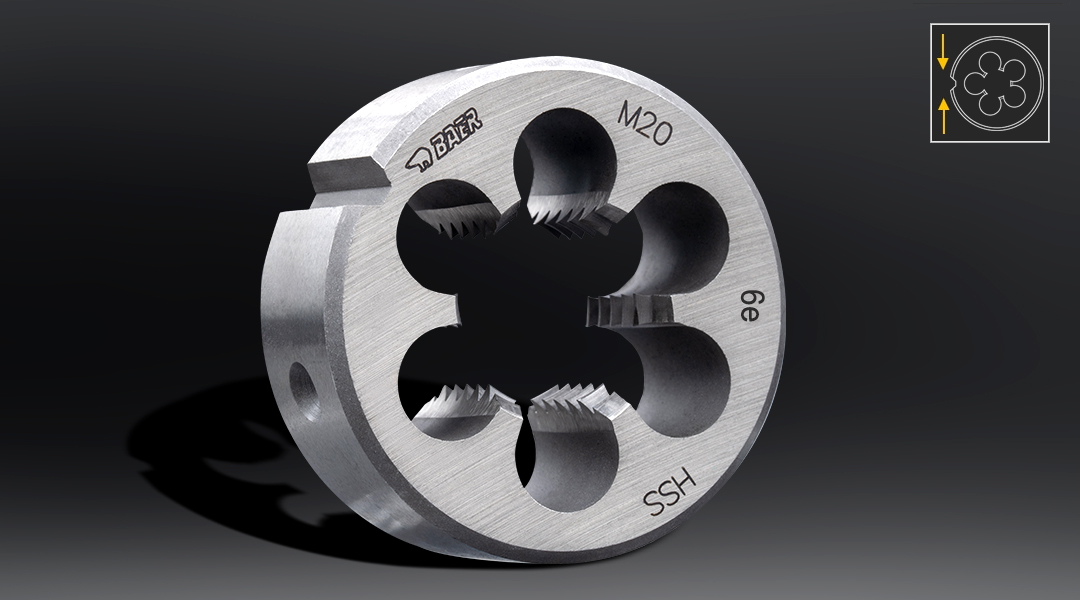

With their unique industrial quality, our BAER dies help you produce perfect external threads. They are equipped with three or more cutting edges. Between them are practical holes that optimally absorb and remove chips.

The material our quality dies are made of is high-speed steel (HSS or HSSE). This makes them particularly durable and robust.

In addition, their construction is so simple that they can also be handled without much effort. They can also be used from both sides and take up very little space. Since they are symmetrical in design, you can use them for cutting in both axial directions. All in all, at BAER you get high-quality cutting irons at an optimal price.

Advantages of the die on a view

- Small space requirement

- Adjustment without effort

- Use on single and multi-spindle machines

- Simple tool set-up

- Use from both sides

Excellent quality at a good price. That is BAER.

You would like to get more detailed information? Contact us.

Buy the right threading die for every application

In the online store of BAER Tools you will find a wide range of cutting tools for different materials and applications. A brief overview of our range will help you choose the perfect variant for your needs. Among them you will find both round and hexagonal cutting irons.

The right cutting iron for normal applications: Round threading dies are ideally suited for quite normal applications. They are available in many different sizes, so you are guaranteed to find something suitable for your application. Left-hand threads can also be produced optimally with one of our round variants especially for left-hand threads.

Threading dies for stainless steel: For stainless steel it may be a special die. That's why you'll also find dies that are especially suitable for rust-resistant stainless steel. This is because they have additional power and thus also cut more resistant material with ease.

Threading dies for brass: Even for brass, the die needs to be chosen wisely. We make it easy for you and offer a wide range of threading dies that are there to cut brass with ease. They are designed in a special way to ensure optimum chip removal even on smooth surfaces. This simply averts the risk of a built-up edge that you have when machining with a normal specimen.

Undersize threading dies: A round undersize die is the perfect choice when the surface of the material needs further treatment after cutting. For this purpose, this particular die has an undersize tolerance of 6e. Thus, it still complies with the common standard even after the subsequent further processing. You can therefore still galvanize it without any problems after cutting.

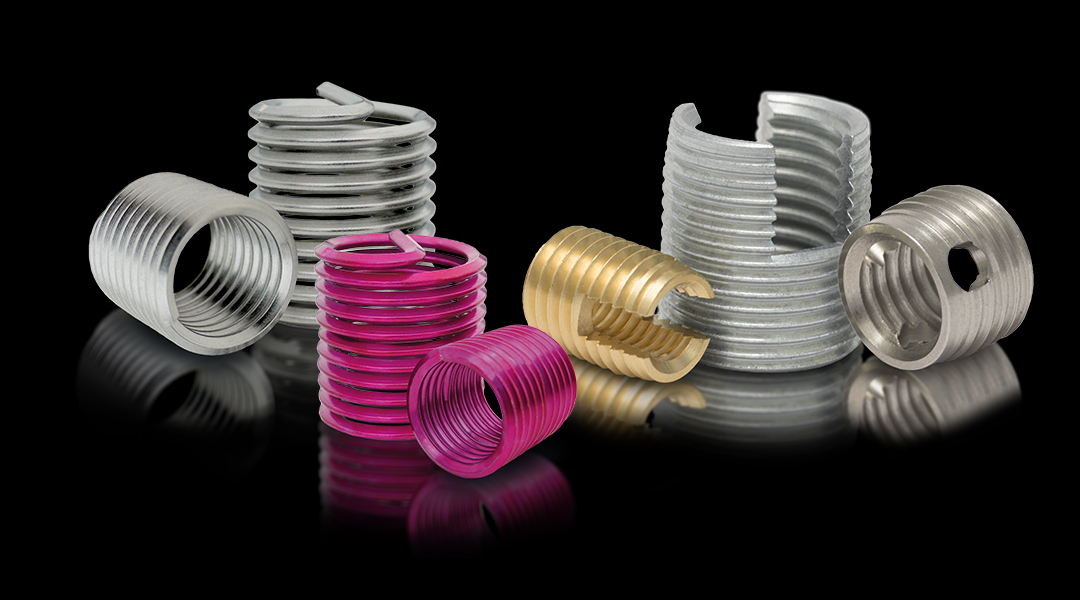

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.

Cutter with external dimension: Even if you are looking for a cutter with external dimension, you will find it at BAER. With a diameter of 25 mm and a height of 9 mm, it can be used perfectly together with a die holder.

The perfect cutting iron for repair and recutting: A hexagonal cutting iron is perfect for this. Even in places that are difficult to reach, the hexagonal cutting iron does an excellent job. Of course, you can also use it to cut new threads. It cuts plastic just as reliably as steel. You can also order our hexagonal die specially for left-hand threads.

BAER-Special dies: Even in very special cases, BAER will not leave you hanging. We also offer a number of special cutting tools that are ideally suited for machining special nickel alloys. If you still need a very special custom-made product, please do not hesitate to contact us. We can also provide reliable assistance in special cases and will be happy to have something made to your individual requirements.

Once you have found the perfect tool for your needs, it is important that you lubricate it well during use. You should also fix it well during use so that it does not slip.

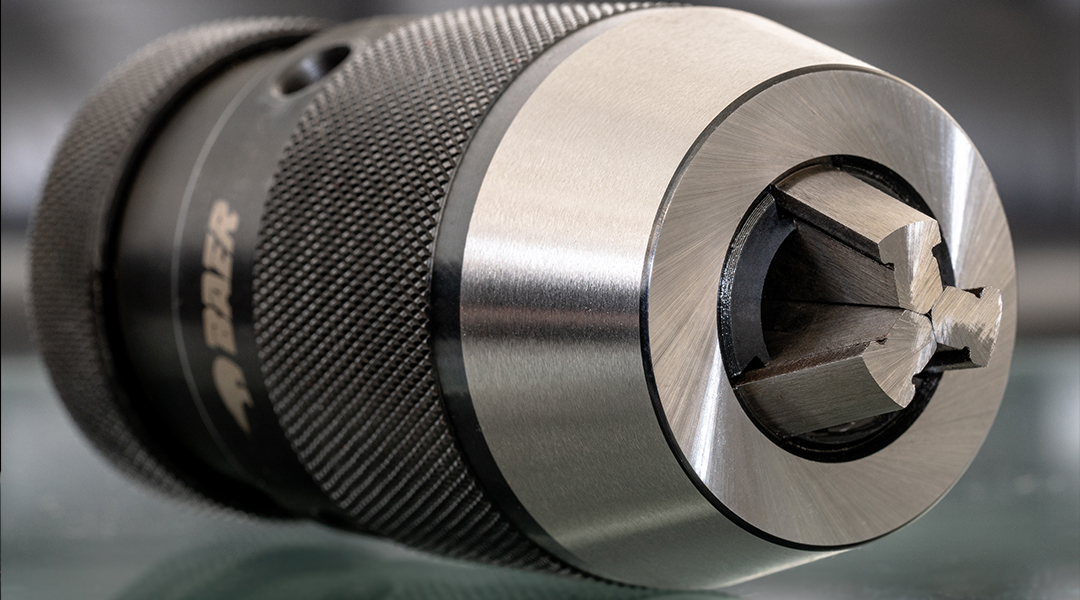

Discover suitable accessories for our dies

BAER is also your contact when it comes to the right accessories for your die. Because in our online store you will find practical accessories that will make your cutting iron even more efficient.

For the manual use of your cutting iron, for example, actuation tools are particularly practical. They help you to operate your tool in the best possible way.

Buy threading die in our online store

When you buy threading dies at BAER, you can be sure of a particularly pleasant shopping experience. Because our many payment options such as PayPal, credit card, purchase on account and much more make your shopping experience particularly convenient. What's more, in addition to outstanding quality, you can also count on safe and fast shipping. For 40 years, BAER has been your reliable partner in thread machining. Choose an experienced family business and benefit from high-quality tools and professional advice.

Do you still have questions? Then contact us via our contact form or by phone. We are looking forward to your inquiry!