Tap wrench and die holder - accurate fit and solid

With our actuating tools (tap wrenches and die holders) from BAER manual tapping is child's play! In industry, the machine tap is often used, but there are also situations where taps are still operated manually, for example when re-tapping or re-tapping threads.

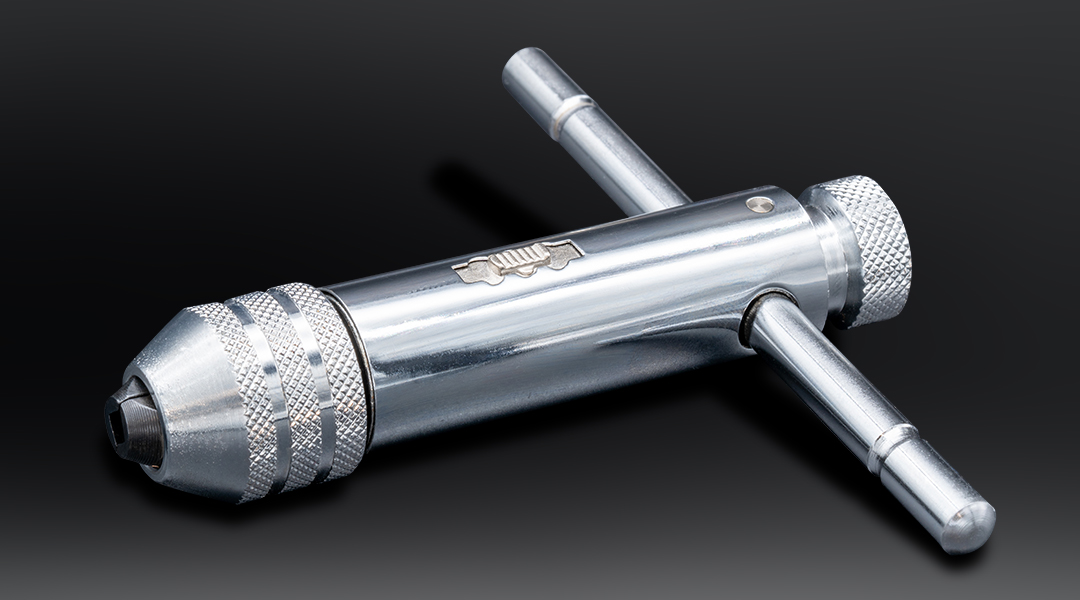

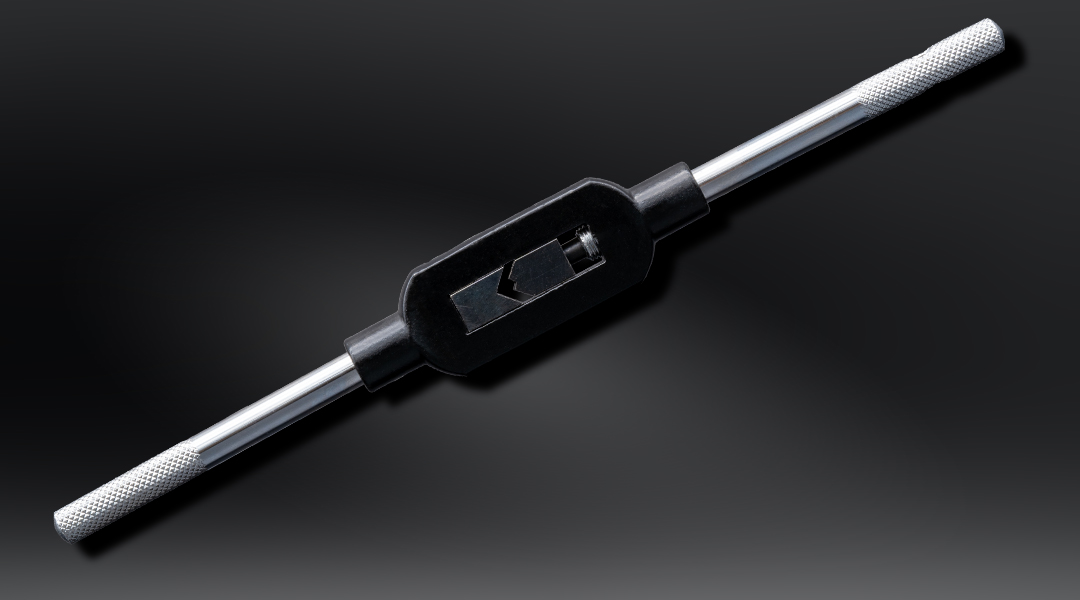

Our tap wrenches are the perfect solution for clamping the tap during manual thread cutting. This way, the tool sits bombproof and supports you in exerting greater leverage. Of course, we also offer adjustable tap wrenches that allow you to clamp different sized taps.

The sturdy zinc die-cast winch bars are particularly easy to operate and not only allow you to change tools quickly, but also have a lever that can be turned off on one side so that you can also work with the winch bar in hard-to-reach places.

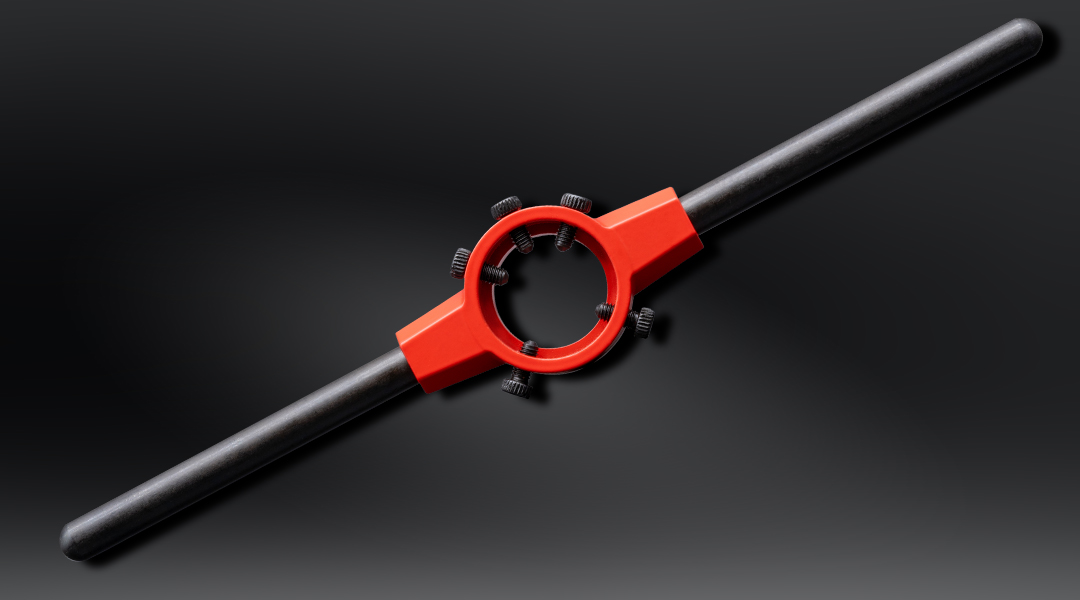

Die holder and winch iron - appearance and use

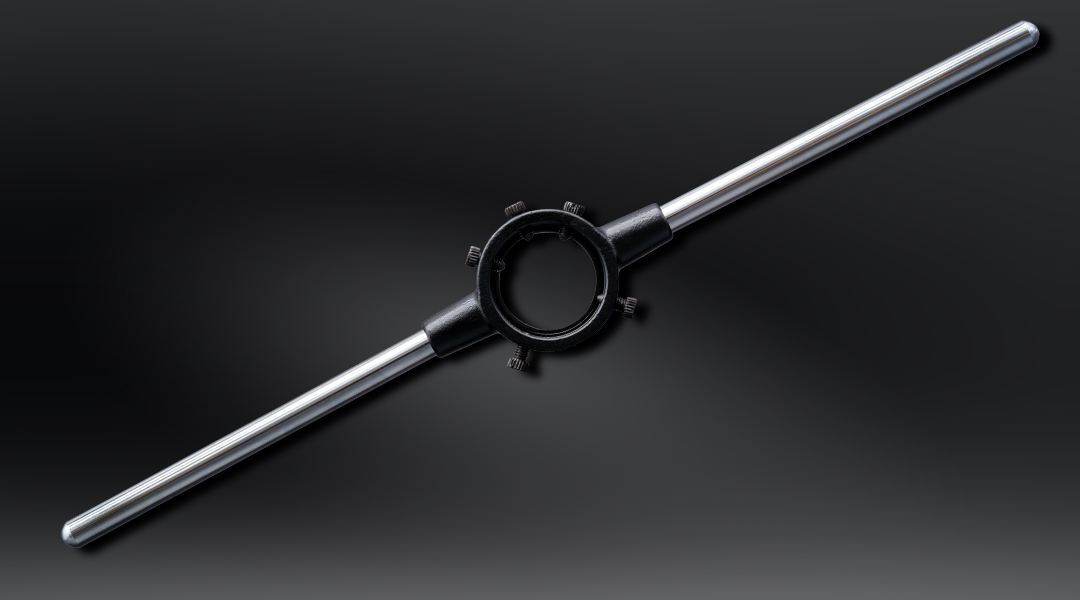

In addition to the tap wrenches as holders for taps (internal threads), our actuating tools also include die holders. From this point of view, the tap wrench is also not a hand tool, but rather a tool handle or holding device.

Both tools have been known for a long time, but today they are manufactured in a more sophisticated way

- The winchiron has been in use for more than 100 years and has remained virtually unchanged, although the material has of course improved. What was made with gray cast iron back then is now mostly made of zinc die cast or high quality cast steel, making it stronger and more durable than before.

- The die holder is a more recent development that was unknown 100 years ago. At that time, the external threads were cut with cutting lumps and later replaced by round dies. Today, the die holder is also usually made of zinc die casting or cast steel.

We can offer you dies and die holders of the highest quality for precision-fit work in different variants.

Both serve as tool extensions for manual work

Extensions and tool holders for manual operation make the use of taps and dies possible in the first place. The adjustable holding tools are made of zinc die-cast or steel. They apply enough torque to the taps and dies so you can cut your threads by hand.

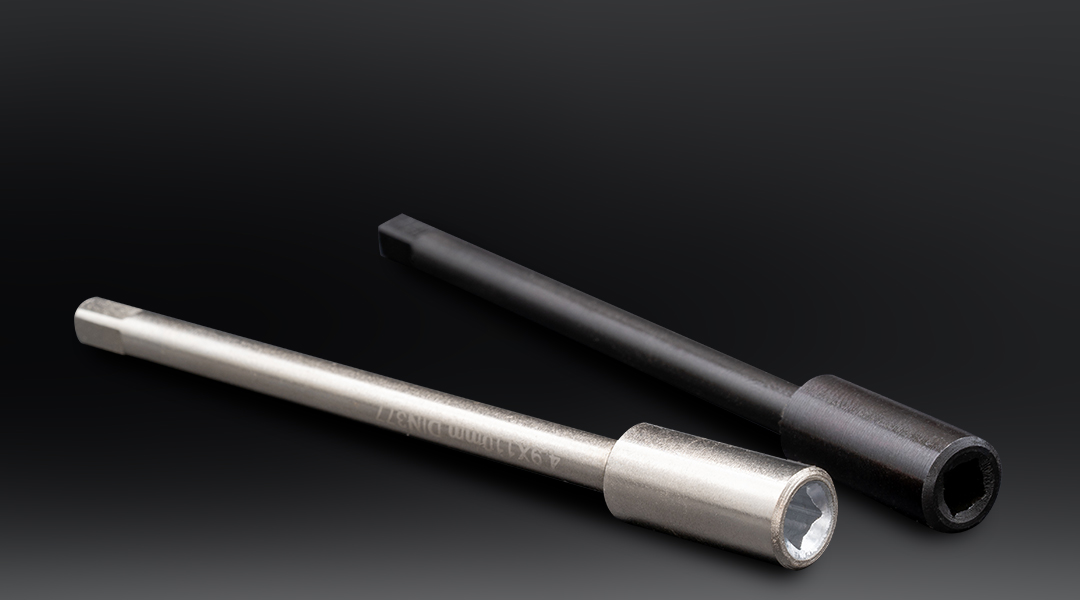

The tap wrench gives you more leverage and extra torque as you work. This helps whenever you need to work in tight spaces with small hand tools. The extension that the winch iron provides gives you more reach and allows you to work more effectively and precisely.

Differences in shape tap wrench (square) and tap holder (round)

Every tap manufactured according to DIN has a square at the end of the shank. To ensure that the tap and its square end fit together, the DIN 10 standard defines the dimensions for the outer square end of the tap.

A tap wrench usually consists of two metal rods as well as a central part with two locking jaws, which allow flexible fastening of the tap. Depending on the product and design, you can get different length tap wrenches with different maximum values of the clamping jaws.

Dies, on the other hand, are round and have grooves or holes on the lateral surface. The dimensions for the die diameters, heights and the mounting holes/grooves are specified in DIN EN 22568 (formerly DIN 223 B). This ensures that corresponding dies fit into the respective die holders.

BAER-Tool holders are stable and durable. Convince yourself.

Difference in use:

- The die holder is used for cutting external threads with a die

- The die is used for cutting internal threads with a tap

Do you have any further questions or do you need product details, for example about our sets and assortments, which you cannot find in the product description in the store? We are at your disposal for all desired information!

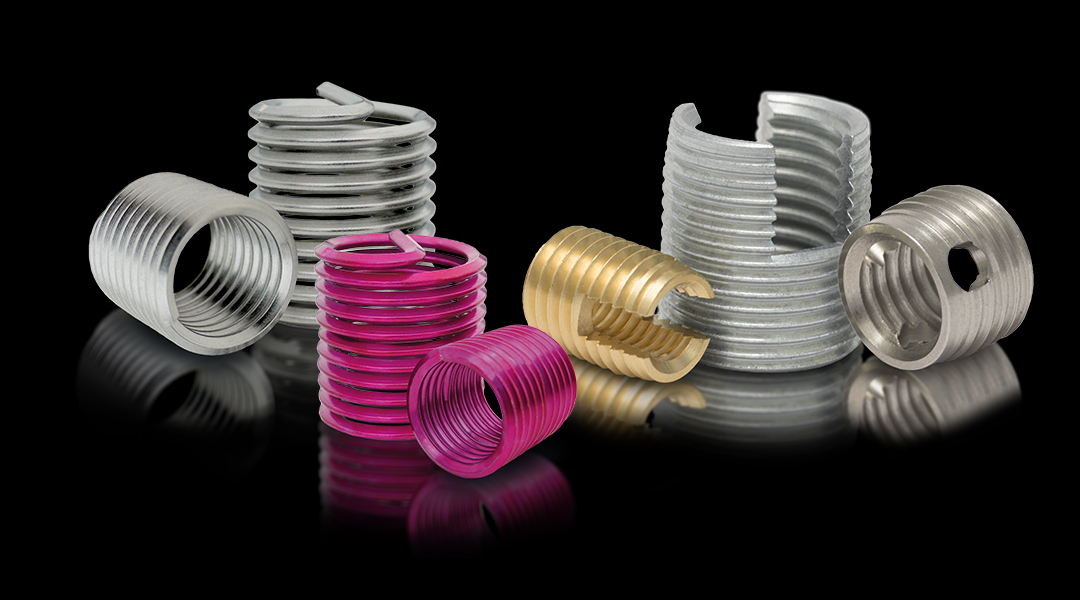

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.

BAER Top products in the range of die holder and winch bar

In our extensive range you will find a wide selection of winch bars and die holders for everyday use.

We have recorded some examples for you below in the brief overview, please inform yourself in detail about properties, functions, material and other important points in the detailed product description of the store. Of course, you can also contact us at any time if you need more information about the products.

Please also note that we are constantly adding innovative and high-quality tools to our store, so the following overview is only a snapshot:

- Tool Ratchet for taps - tool with ratchet in short or long version for taps with square shank; easy to operate; right and left rotation adjustable; ideal for working in confined spaces

- Adjustable PRO tap for taps - holding tool for manual cutting of internal threads; highest quality (zinc die casting); robust and stable; easy handling

- Adjustable steel tap holder for taps - all-steel design for higher torques; stable and durable

- PRO die holder - for holding round dies, according to DIN; heavy-duty model made of die-cast zinc, wear-resistant.

- Steel die holder - DIN standardized cast steel version in highest quality for best results

- Die guides - for a straight cutting direction and a perfectly plumb external thread

- Tap extensions - ideal for deep internal threads, made of solid steel, also suitable for high torques, DIN 10 version.

Order die holder, ratchet and other helpful tools now online from the expert

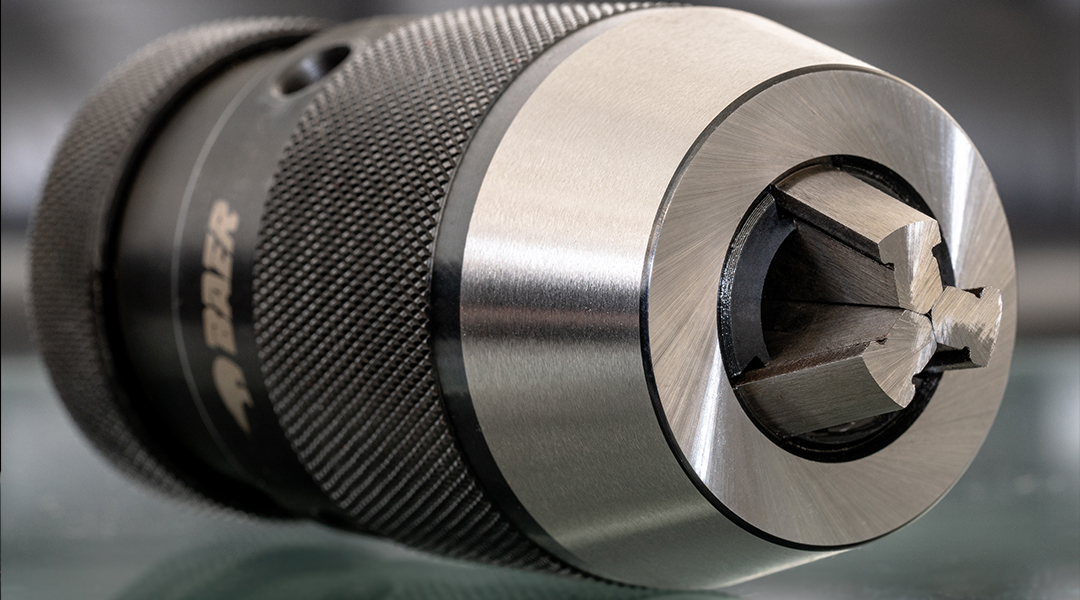

We have extensive expertise in the development, manufacture and sale of taps, drill chucks, wire thread inserts or self-tapping thread inserts. In our clear and comprehensive store, you can conveniently order various high-quality products from these areas online .

As thread professionals, however, we not only offer you a standard range, but we are constantly developing new modern tools and also offer you the individual special production of tools according to your ideas and for your special application.

What counts for us above all is the highest quality, good service and customer satisfaction . At the same time, we do not disregard our responsibility for the environment and have aligned our procurement and production processes with sustainability in mind. Short distances, local production, certified suppliers, green electricity, recycling and environmentally friendly disposal of used oil are part of our daily routine.

We would be pleased to convince you of our expertise, high quality and good service. If you are interested in our winch bars or any other product, please feel free to contact us so that we can help you with your selection and answer any open questions you may have about the products. You can always reach our competent customer service by phone or in writing. The best way is to contact us right away.