The top 10 types of threads

there are many types of threads, so it's easy to get confused. If you have already worked with threads or looked around for a suitable tap, then you have certainly noticed this. Perhaps you have even asked yourself whether such a variety is really necessary. After all, it doesn't exactly make the search for the right tool any easier.

The different thread types all have their purpose. You should be a bit familiar with the thread standards if you want to avoid confusion. Fortunately, the subject is not as complicated as it may seem at first glance. If you know a few common thread types and can correctly assign the thread designations, then you are already on the safe side. We've compiled our top 10 most common thread types for you. First, let's take a look at what constitutes a thread type in the first place.

How do the types of threads differ?

Each type of thread has an individual profile. This is made up of values such as the flank angle and the pitch and determines exactly how the thread looks and behaves. The thread profile also determines the area of application for which a thread is suitable. Based on this, common thread types can be grouped into different groups.

International differences

Different standards have become established in different parts of the world. Particularly widespread are the American Unified National thread types and the British Standard thread types, which dimensions are specified in inches in each case. In Europe, the ISO thread with metric dimensions is the most widely used. Incidentally, the boundaries here are no longer as sharp as they were a hundred years ago. Even in Germany, you can encounter an inch thread at any time!

Fastening or movement thread

We find fastening threads everywhere where threads are to create a firm hold. Screws and nuts are good examples. In addition, there is also the thread type of the movement thread, which transmits a movement. Think, for example, of the spindle of a lathe. You can often recognize these types of threads by their profile, which is clearly different from tapered fastening threads.

Right or left hand thread

This is less a question of the type of thread and more a question of the direction of rotation. Most threads are right-hand threads and can be tightened by turning them clockwise. Left-hand threads work the other way around, these types of threads are tightened by turning them counterclockwise. They are used whenever a rotational movement could loosen the thread, such as on a bicycle pedal on the left side. You will also encounter left-hand threads in situations where accidental unscrewing or incorrect connection should be avoided (e.g. gas bottles!).

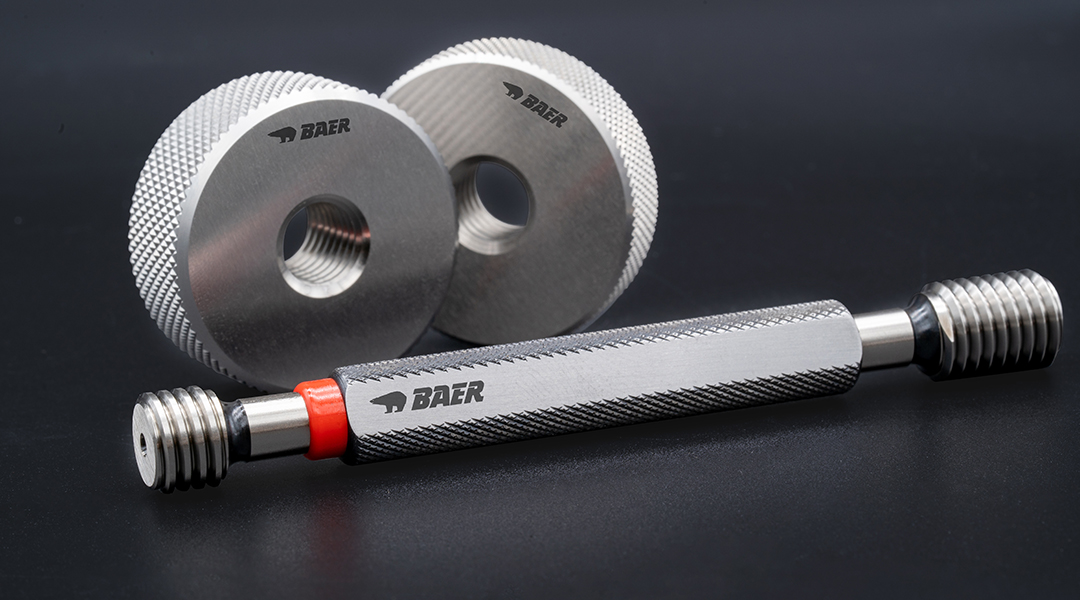

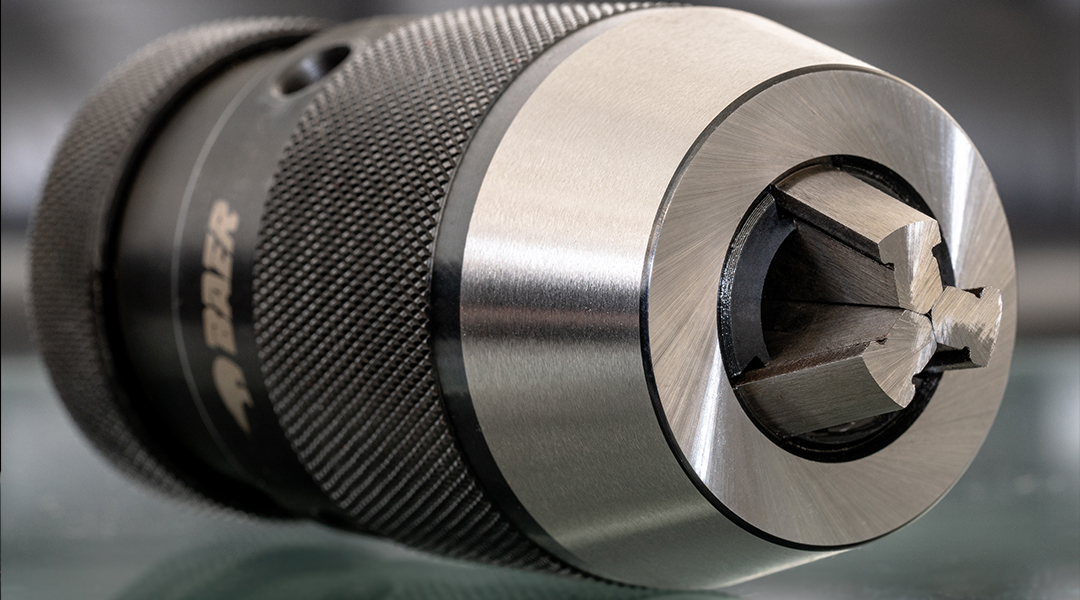

BAER UNI products – All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service live times. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.

10 common thread types you should know about

The ISO metric thread (M)

You should already be familiar with the ISO metric thread (also called metric standard thread), as this is the most common type of thread in Europe. The thread designation consists of the letter M and the outside diameter. The flank angle of this thread type is 60°. It is often used for fastening screws and nuts.

The ISO metric fine thread (MF)

The ISO metric fine pitch thread is characterized by a smaller pitch and a smaller thread depth than the ISO metric standard thread. It has good self-locking properties and is often used for adjusting screws, as the small pitch allows very fine adjustment. In addition, the metric fine thread requires less space due to the small depth and is therefore used for thin-walled components. The thread designation is MF.

The trapezoidal thread (Tr)

The profile of the trapezoidal thread is in the form of an isosceles trapezoid and bears the abbreviation Tr. The flank angle is 30°. The trapezoidal thread is often used as a movement thread , for example, it is often found on the lead screws of lathes. The trapezoidal thread is also an ISO metric thread with all dimensions in mm.

Unified National Coarse Thread (UNC)

The UNC thread is the American equivalent of the ISO metric thread. Its flank angle is also 60°, and all dimensions are given in inches. The thread designation is made up of the number of threads per inch and the abbreviation UNC.

Unified National Fine Thread (UNF)

The UNF thread is the fine thread to the UNC standard thread - analogous to standard and fine threads in the metric ISO thread. Here, too, the number of threads is indicated in the thread designation in addition to the abbreviation. UNC and UNF are widespread far beyond the borders of the USA and are also frequently used in Australia, India and Japan, among other countries.

Unified National Special Thread (UNS)

The UNS thread is a special thread that allows special combinations of diameter and pitch. It is mainly used in Australia, Great Britain, New Zealand and the USA.

National Standard Taper Pipe (NPT)

The NPT thread is a pipe thread that is primarily used for pipe fittings. It is not self-sealing and therefore always requires additional sealants. The flank angle is 60°.

British Standard Whitworth Coarse Thread (BSW)

The British coarse control thread is often simply referred to as the Whitworth thread - after the British engineer Joseph Whitworth. It is the British equivalent of the M or UNC thread, but the flank angle of the BSW is only 55°. The thread designation consists of the abbreviation BSW and the diameter in inches.

British Standard Fine Thread (BSF)

There is also a matching fine thread to the British standard thread, the BSF thread. It also has a flank angle of 55° and bears the thread designation BSF followed by the diameter in inches.

British Standard Pipe Parallel (BSP)

Finally, there is also a pipe thread among the British thread types, the BSP thread. The abbreviation for the British pipe thread is G. Although the thread designation also includes an inch, this does not correspond to the outside diameter. This is due to historical reasons, as the specification refers to obsolete pipe dimensions that are no longer used today.

These were our top 10 most common thread types you should have heard of. At the BAER Online-Shop from the tap manufacturer BAER you will find threading tools for these and many more thread types as well as the matching screw taps. So take a look. And If you are unsure which thread type is right for you, feel free to ask our customer service.